Skidmore-Wilhelm expert and proprietor Mr. John O’Brien and industry guru Carmen Vertullo delve deeply into the applications, uses and origins of tension bolting’s most unique and essential tool. Discover simple yet effective lubricating techniques, little known but deadly hazards of improper bolt tensioning, and exclusive training opportunities during this wide reaching conversation. PLUS: Mysterious K-factor talk aplenty! Run time: 01:23:40

—

Listen to the podcast here

Important Links

- Carmen Vertullo on LinkedIn

- Skidmore-Wilhelm

- John O’Brien on LinkedIn

- Fastener Training Institute

- Tungsten Capital Partners

- IMPACT | Ironworker

- Skidmore Training

- Carver Labs

The Skidmore-Wilhelm Story

Unveiling Skidmore-Wilhelm: A Legacy of Torque Tensioning

It is Fully Threaded Radio, the voice of the FCH Sourcing Network. Eric Dudas is with you here again. It’s episode 209, right on the heels of our last episode. This one is going to drop January 23rd, 2025. This episode is a conversation with a good friend of the show, Carmen Vertullo, along with John O’Brien. He’s the President and Co-Owner of Skidmore-Wilhelm, the widely used and venerated torque tensioning tester that you’ve read Carmen speak about so often. That is in such wide use, especially in the area of structural bolting.

This is a great conversation. We don’t just talk about torque tensioning. That could get a little dull, even for folks who are into that kind of thing. They cover some great stories and some application issues. We even touch on an issue that affects everyone who drives down the highways. This is a shocker. We also get into some of the specifics of Skidmore-Wilhelm devices that you might not have been aware of. It’s overall a lot of fun and very informative. I’ve been wanting to do this one since I met John during Fastener Training Week.

He’s a great guy, full of knowledge, and a mad scientist, as you’ll soon read. Carmen and he play off each other well. You’re going to enjoy this one. Fully Threaded Radio is made possible only with the help of our partners. Let them know you appreciate it, everyone. The title sponsors of Fully Threaded Radio. Brighton-Best International, tested, tried, true, Brighton-Best. GOEBEL Fasteners, quality the first time. Go GOEBEL. Star Stainless, right off the shelf. It’s Star. Fully Threaded is also sponsored by Buckeye Fasteners, BTM Manufacturing, Eurolink Fastener Supply Service, Fastener Technology International, INxSQL Software, Fastener Fair USA, J.Lanfranco, Solution Industries, Volt Industrial Plastics, and Würth Industry North America.

Let them know you appreciate it, folks. Let us know whatever is on your mind about the show, FCH Sourcing Network, or anything related to fastening or the fastener industry. The email is FTR@FullyThreaded.com. Again, you’re going to like this conversation and probably learn a few things. You’ll definitely have another reason to stop by the Buckeye Fasteners booth next time you see me at a trade show, because you’ll find out. It has something to do with ChapStick. There’s your hint. Thanks for clicking in, everyone. Here’s that conversation with John and Carmen.

—

Here we are with the first full-length segment of the 2025 show season. This is one that I’ve been wanting to do when I participated in the Fastener Training Institute Fastener Week in Cleveland and had a chance to travel to Independence with my good friend, Carmen Vertullo. We’ll let that unfold as we talk further. That’s setting this up enough. Right now, I’d like to introduce two guests that I’ve got with me, Mr. Skidmore and Mr. Wilhelm. Which one of you is which? Fill me in.

That’s depending on the day. One was a sales guy, and one was the engineer. I’m probably more of the sales guy, but that’s okay.

Let’s fill in the blanks on that one. John O’Brien, you’re the big cheese over there at Skidmore-Wilhelm. Our other guest is Carmen Vertullo. I’m so glad to have you guys on.

Thanks, Eric. It’s great to be here.

Thanks for having us.

There’s a story that goes with that little intro, isn’t there?

First, how Skidmore met Wilhelm. Is that what you’re referring to?

No, he’s talking about something else. You probably don’t even remember this, John.

You warmed this one up for me, Carmen. Fire away on that.

Several years ago, John, you and I did a floor show. I guess you could call it training on the bolt tension calibrator at the Vegas Fastener Show, the IFE.

I remember.

We were up there on the stage. We had the unit up there. We had some videos. I started off by saying what we’re going to talk about. I said, “I’m Mr. Skidmore. This is Mr. Wilhelm.” Some people laughed, but I had to clarify that it was a joke later. A lot of people didn’t get the clarification. People were thinking I was Skidmore, and you were Wilhelm for the longest time.

Hopefully, they treated you well.

It came with great honor.

That’s great to hear.

Those are venerated names to anybody who has been in the industry for a while. Carmen, you certainly mentioned Skidmore, Wilhelm, torque tension, and testing equipment frequently in your various works. It’s a huge topic technically. Where do we dig into all this? I guess we could start by talking about the subject of torque tension in general before we delve into there.

Before that, Eric, I’d like to tell you something about John that he might not even know about himself. I’ve known him for a while. We’ve been in classrooms together. I’ll tell you how he came into the Fastener Training Institute back in the day later on. John does more than the Skidmore-Wilhelm company. He’s got a group of companies under his umbrella, Tungsten Capital Partners. I don’t think he has any idea how significant the Skidmore-Wilhelm bolt tension calibrator and the associated equipment are in the industry, because he has other lines. It’s a brand. He probably has three or four other things going on, at least, that are equivalent to this in his business life or better. I don’t even know.

Rarely do you see a product in any space, let alone fasteners, that does not have significant competition. John has no competition on this product. I don’t see another brand out there. Skidmore, you would think it’s a generic word, but it isn’t. When people talk about the Skidmore, they know exactly what you’re talking about. There’s only one place to get it. There’s only one place that makes it. There’s not another company in the United States that I know of that makes anything like it. You would think it would have long ago been replaced with some electronic gizmo.

No, it’s ubiquitous. It’s everlasting. It is the tool that makes all the difference in the world to make sure not just our structures go up reliably, but also in plants, automotive, and other places. We think of the Skidmore-Wilhelm mainly in the context of structural bolting. That’s probably its main role, but it’s used in many other torque tension tightening strategy applications, from medical to automotive. I use several of them here every day in our lab. I hope John knows that. If he didn’t know it before, he knows it now. So does everybody else.

It’s been a fascinating journey. My partners and I bought the company in 2006. We knew that it was involved in structural steel. Our product had to be used. We started revamping and revitalizing the company in terms of technology. When we bought the company, every recalibration of every Skidmore was on a note card, handwritten. Every time it had come back in, we would handwrite a new journal entry on the note card and determine that it had been recalibrated that year. I wrote a piece of software that automated that whole thing. It was fascinating when we were converting it. All of the early customers of Skidmore were Ford Motor Company and General Motors. They were all industrial fastener companies and a few structural steel.

The problem of torque tension back in the early 1950s was so prevalent. These companies needed to figure out what they were doing in terms of the torque tension relationship. I was floored when I saw the who’s who of lists of people that were using our equipment, or back in the day, did use it. In most instances, they figured out what they were doing. They don’t use the Skidmore every day. In structural steel, they have to use it every day because it’s that important. Thank you for mentioning it, Carmen. We try not to take advantage of our monopoly status. It’s still a relatively small company. Our main focus now is supporting the people who are nice enough to use our products and get them solutions to the problems that they encounter.

The Birth Of A Bolt Tension Tester: A Cleveland Story

John, just to be clear, to your knowledge, when did the tool actually come into existence? When was it first used?

It’s funny. The story behind it was that there was a high school that was being built in the Cleveland area. Skidmore and Wilhelm had started a machine shop. I can tell you that story if you’d like. The engineer of record who was building this high school was on his first project using bolts instead of rivets. He was a smart guy and said, “How do I know these bolts are tight?” Somebody directed him to Dick Skidmore, who was the Skidmore of the Skidmore-Wilhelm founding.

He was an engineer from Case Western Reserve University, a fine university here in Cleveland, and an engineering school. My partner also went there. Over the weekend, he invented a device that would allow you to at least measure the tension in a bolt. You could correlate that to your torque wrench. That was how you knew that you were getting a tight bolt. It was 1954. The reason I know that is because we have all the records of every unit we’ve ever sold. Coincidentally, I had a customer show up with serial number 102. They started at 101. It was the second unit ever made. It was still in use 60-some years later. I forced them to sell it back to me. I gave them a brand new unit in exchange. I have unit 102 back in our facility.

That’s a great story.

I need to figure out how to do something with it. It’s currently sitting in the closet somewhere.

That baby needs to be enshrined in your facility there.

When they induct Carmen into the Bolting Hall of Fame, maybe we can put this Skidmore next to it, because he’s been integral to our growth in this industry.

Inside The Mad Scientist’s Lab: Skidmore-Wilhelm’s Operations

It needs to go somewhere for sure. The IFI is right down the street, practically, from where you are. Let me set the picture for our audience a little bit. I went there again with Carmen. He actually dragged in his suitcase, all the way from San Diego, a couple of your units that he wanted to have tweaked. I don’t know exactly what was going on there, Carmen. You can tell me. He had these things packed in suitcases. He needed something.

After one of the classes, we drove over there together. We went in by the loading dock in your facility. It’s like a mad scientist’s lair in there. This is all kinds of stuff. There are shelves everywhere. I’ve seen Fastenal branches with fewer parts on the shelves, and all kinds of stuff, too, like Carmen was saying at the beginning of the segment here. You’re doing a lot of things over there. Into this facility, we walked with these two units. I didn’t go in the front door, so I don’t know if you have much of a showpiece lobby there.

We do not. We’re an old-school industrial company. We have very little office space. It’s all in the plant. As you can imagine, when you have a company that was started in the ’40s, and some of our other companies were started even earlier than that, you collect a whole bunch of memorabilia that you just can’t seem to figure out how to get rid of or make something out of. We’ll figure it out someday, I suppose, but we have a lot of stuff here.

From time to time, people bring up the idea of a fastener museum. There have been a couple of attempts at that. Mel Kirsner, was it, Carm? It is out there in California. He had one for many years that eventually burned down. You know that story, right?

I had the privilege of being able to visit that museum once. Back in the day, it wasn’t Pac-West. It was the Western Association of Fastener Distributors meeting. We went here in Alpine near San Diego. One of our infamous fires, thank God, as we’re here, Los Angeles is burning to the ground, but we’re relatively safe in San Diego. I hope we stay that way because all of our firefighters are up there. That museum was amazing. It was made entirely out of wood. I don’t know if it’s pine. It looked like knotty pine. His beautiful home and everything were lost.

A lot of material he had. Do you know what year it was that it burned?

I do not, but I’ll bet you a quick Google search will tell me.

I’ll have to get something together on that. For years, we’ve been threatening to do a retrospective on that. I guess it’s due. Looking to the future, we’ve heard other folks. I know that Brighton has talked about doing something in their Cleveland facility, too, so that might be something we could connect dots on here.

I know it was before the days of the iPhone or phones with cameras on them, because I remember having a digital camera with me. I took some pictures. I wish I could find them. Hopefully, there are others who have taken pictures. We could find something around that.

The Evolution Of Skidmore-Wilhelm Models: MZ, MS, And HS

What was it that we were doing that day with those two units that you brought over to John’s facility? What were you trying to do?

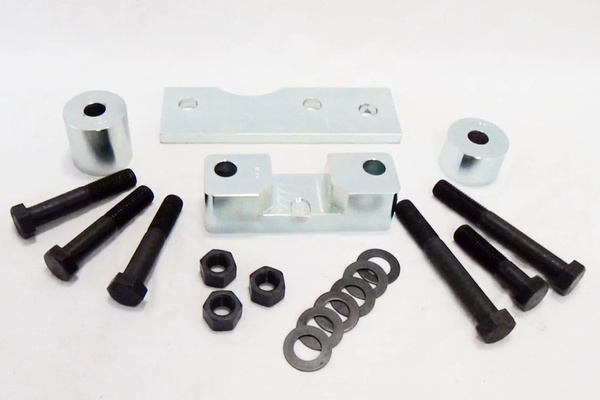

Here’s the interesting thing. By the way, Eric, I believe in my Fastener Training Minute, I transposed the MS and MZ Model numbers, so we need to fix that, or at least I need to look at it and see. In the structural bolting area, there are two models. The MZ is the older unit. Is that right, John? It goes to 126 kips?

Yes, that’s our newest unit. That’s the lion’s share of Skidmores we sell.

Before that was the MS?

Correct.

It was the same unit, but made out of steel?

Yes.

What is the big one that goes to 170?

That is currently the HS. That started as the H.

I have two of them, both of which, by the way, were acquired at the graciousness of John. He supports me a lot when I need a part. Thank you, John. I’ve probably sold several dozen of these. I’ve literally forced people into buying them and shamed people into buying them.

I know. I’ve heard those pitches, Carm, on the show and all other places. John, you ought to think about at least setting Carm up with a t-shirt, an ashtray, or something.

I have this Model HS. Also, I have the MZ. Back in the day, these things were made out of steel. They came in this horrible steel case with a handle. If you carried it, it would cut your fingers off. They were heavy. They were bulletproof. John figured out, when he took over the company, that he could make the housing of the unit out of aluminum. It would still be just as good, if not better. These newer units are made out of aluminum. They’re lighter weight.

They come in really cool Pelican cases with wheels. We needed that on the job site. I’ll tell you about that story. Of my two units, one of them got abused pretty badly. It needed not just a calibration, but some reconditioning. It was leaking. The other one just needed to be calibrated. I happened to be coming back to Cleveland for whatever was going on, all kinds of good stuff, a trade show, or stuff at the IFI.

They are heavy, so shipping them is expensive. The downside is that when these things are in shipping and when they’re in calibration, you don’t have them available for use. I needed to minimize that amount of time. They got these cool Pelican cases. I’ll put them in the Pelican cases. We’ll take them. It turns out in the Pelican case, they were over 50 pounds. I took them and wrapped them in a moving blanket. I put them in a standard suitcase about the size of what you could do in a carry-on on an airplane. Southwest gives you two free bags, so I shipped them on Southwest.

Those bags don’t have much of a weight limit. They’re about 50 pounds. I was able to get them under that. I took them back there. I showed up there on the loading dock with these two suitcases. The guys came out, and they shook their heads. They said, “What the hell is this?” John said, “Take care of them. He wants to pick these up at the end of the day.” It just worked. I picked them up at the end of the day after our session at the IFI, got them home, no downtime, calibration certificates, and everything was gold.

I’m not saying that Skidmore can do that for everybody or anybody in particular, but their Service Department is amazing. They’re very competent people. It was really cool. They had some units in work when we were there that we got to see and explain to us how the calibration works. That was a cool trip. I don’t think that most labs do a lot of structural bolting work. I will tell you this. Most labs, like, for example, the Division of the State Architect labs that are certified by the state of California, of which we’re not one yet, they don’t know much about fasteners. They commonly make errors in all kinds of structural bolting and other fastener testing applications. We get to straighten them out from time to time.

As bulletproof and idiot-proof as Skidmore is, there are still things that people can do wrong to abuse the tool or to get incorrect results. In some cases, they don’t know how the tool works, so they don’t understand how to troubleshoot it. Fortunately, if someone is trained, the RCSC, the standard Research Council on Structural Connections, their guide for the installation of high-strength bolting, tells us whenever you are doing the PIV test, the pre-installation verification test, which is the main use for the bolt tension calibrator, and if something is not right, you should stop and investigate it before you proceed.

If something doesn’t seem right, stop and investigate before you proceed—before you put the bolts in the steel, reject the bolts, or have a meltdown trying to send them back. Find the cause first. Share on XBefore you put the bolts in the steel, before you decide to reject the bolts, and before you throw up all over the place, have a meltdown, and try to make your supplier take the bolts back, investigate the cause. It’s not common, but it’s certainly possible that the cause can be that the user doesn’t know exactly how to use the tool, how to read the tool, or what the value should be. It’s important that they be calibrated. I don’t know, John, do you ever see one come in and it’s out of calibration, or do they hold pretty well?

Calibration And Durability: The Reliability Of Skidmore-Wilhelm

Usually, they hold very well. If it’s out of calibration, it’s usually because it’s been damaged. Believe it or not, we do see some units that go to calibration houses. They try and adjust it on their own because their setup isn’t exactly right. You can adjust the gauge and put it out of calibration. That’s typically what we’ll see. If something is more than, say, 5% out of calibration, it usually means that it’s been manually put in that state. It’s rare for us. We calibrate to within 1% of reading. It’s rare for us to get a unit back that’s out of that tolerance by more than 1% or 2%.

As these instruments go, that’s a very good standard. There are certain other things that you learn along the way. When we teach our structural bolting clinics here in San Diego or wherever, these are things that people would never know unless they got to hang around John. We occasionally have abused our tools by exceeding the maximum value on the dial. For example, the MZ goes to 126 kips.

Sometimes, if you’re doing a certain test, like a row cap, and you have to go a number of degrees, I still have a little bit to go, but I’m already at 126. Can I go a little bit further and abuse that or not? Most instrument makers would say, “No, don’t do that because what’ll happen is it won’t go back to zero. You won’t have a good calibration.” John said, “Yes, you can go a little bit past. As long as it goes back to zero, your tool’s good.”

Testing the limits, Carm? I can’t believe you would do that.

You would never know that. It’s not something that would ever be advertised, but it’s a very robust tool.

We have safety factors on the top end so that nothing is going to explode or anything like that. We appreciate it when people keep it below the limit, but know that if you have to exceed the limit, you can. The good news is that we tell everybody what bolt sizes are appropriate for each tool. We sell the accessories. For example, the MZ cannot do a 1 1/2-inch diameter bolt. One, the capacity is not big enough. Two, we don’t sell adapters so that you can test a 1 1/2-inch bolt on an MZ. It’s just not possible. We know that 1 1/4-inch is the top you’re going to see in that unit. We can take a 1 1/4-inch bolt to failure, and still, the Skidmore will survive. No problem.

Speaking of 1 1/2 inches, I’ll just give you the highlight of a story that you can get the details on in the Fastener Training Minute. A steel erector here in San Diego had failed to do the PIV test on some 1 1/2-inch A490 structural bolts, which are the largest, strongest structural bolts available normally. We have some new standards that have stronger bolts than that, but this is, as far as something you could actually buy, the largest, strongest structural bolt you’ll have. You need to have the HS to test this.

They didn’t have one. They couldn’t find anyone who had one. They called John. John said, “Carmen has one.” It was literally the bat phone ringing. Carver to the rescue. We took our HS to the job site, where they had already installed it. First off, imagine the building that needs a 1 1/2-inch A490. These columns look like they belonged in a skyscraper. This building was only four stories, so we don’t understand that yet. We went up in the steel with the HS. The issue was that their tightening method for these 1 1/2-inch A490s was using the direct tension indicator, which is a washer with bumps on it.

That’s how you know that the bolt’s properly tightened. They failed to do the PIV tests with these washers before they assembled this building. Why? We didn’t have a big enough Skidmore, so you just proceed anyway. It is an incredibly bad risk. I don’t know how to say it, but I’ll just use the word stupid for them to have done that. Fortunately, we were able to show up in a short amount of time, do the tests, qualify those direct tension indicators, and get out of there in a couple of hours.

I love that story. You had texted me a picture of the job site that evening. Nothing makes me feel better than putting someone in touch with Carmen Vertullo, because he is the cream of the cream when it comes to people who know bolting. Anytime anyone has a problem, Carmen will figure the problem out. If he can fix it, he fixes it. I’m thrilled that I’m more in the Midwest, but you’re out West. I can rely on you to go visit people when I’m unable. That was great. I loved it.

I have a long list of those stories. I probably talked about every one of them on the Fastener Training Minute at some point, but someday, we should compile them because there are lessons to be learned in every single one of them.

The Dangers Of Improper Bolting: Why PIV Tests Are Crucial

I have some great stories as well. Maybe we’ll get into some of them as we keep talking. There’s some fascinating stuff. It’s amazing to me that there are people who are in the structural steel business trying to get out of this pre-installation verification on the job site.

What? Wait, hang on. Why would that be?

If you don’t know what you’re doing, and you see it as more of a hassle, and a lot of bolt distributors will say, “They passed here, so they’re going to pass in the field as well. Why don’t we just go? We hate getting calls from the field that our bolts aren’t working.” I always say, “Time out. There’s a reason that they aren’t working in the field. We need to figure out what’s different between what you did at your facility using Skidmore equipment and what they’re doing at the job site using the same equipment. Why isn’t it working?” Instead of saying, “We should just stop testing,” because obviously, they don’t know what they’re doing in the field.

Let’s train them how to do it in the field as well. I’ve been training ironworkers since about six months after we bought the company. I started training ironworkers at the Locals. It’s amazing the change in their attitude about the Skidmore testing once they realize what they’re doing, and once they determine when there’s a problem and how to troubleshoot and fix what’s going on. A lot of times, it has to do with lubrication on the bolt. It is being compromised.

For example, with tension control bolts, they rely on the lubrication because they’re misnamed. They’re actually torque control bolts because the spline breaks off in torque. Different climates can affect the lubrication and efficiency thereof. If you don’t test that in the field, yes, they’re going to work great in a 65-degree plant where you’re distributing them, but you put them out at 0 degrees in the frozen tundra, and you’re going to have an issue.

Demystifying The K-Factor: Lubrication’s Impact On Torque

We’re swerving into the infinitely mysterious realm of the K-factor, are we not?

Absolutely. You don’t need to understand what your K-factor is. If you have a Skidmore, you can test it, and you don’t have to calculate what your K-factor is. At least, you know your tightening method using the K-factor as it sits. It is going to give you the result that you need on the structure. That’s important. It’s funny because I also get it from industrial fastener groups every once in a while. My favorite story is we got a call from a group, a small company that was making big industrial dryers for towels and hotels, and that type of thing. They were assembling the drum that went inside their dryer. For years, they went to their distributor and bought 1/4-inch twenty bolts.

They didn’t realize that those bolts were being bought en masse by this distributor for another big company that we all know that I won’t mention. They were following that spec. That big company changed its spec. They were smart. They added a little bit of Teflon to the lubrication on those bolts. The poor little mom-and-pop dryer company starts tightening its bolts. They used to use click wrenches to install these bolts in the dryer drum. When it clicked, the click was actually the bolt breaking because the torque was way too high for that bolt. They were shearing the bolt.

The problem was that the way the device was designed, the bolt was sitting there, so they felt the click. It was actually the bolt breaking. They had no idea because they felt the click. It sat there. They turned the dryer on. Guess what happens? The drum goes flying and everything. When your washer is not properly balanced, you get that noise. It sounds like the house is going to fall. Imagine that in a dryer that’s used to holding 400 sheets at a time. They called me in a panic, saying, “We don’t know what’s happening.”

Luckily, they called me back after the fact because we sent them a Skidmore. They did some testing. Same bolt. They changed their torque spec to install the bolts. Their click wrench went down to 10% of what it originally was. I don’t remember the exact numbers. Say it was 15 foot-pounds. They now needed 1.5 foot-pounds to install this same bolt, just because the lubrication on the spec for the big company had changed, and they had no idea.

For most companies, that’s not something you think about. If you’re making washers and dryers, you’re thinking about making washers and dryers. You’re not thinking about, “The bolt spec is crucial to what I’m doing, in that instance.” I love telling that story because it comes home to a lot of different people who install bolts. Every time I teach a class, I relate it, especially to ironworkers, because I relate it back to guys changing their tires on their car.

Highway Hazards: The Shocking Truth About Truck Wheel Failures

We got to talk about something that you brought up while I was talking to you. I forgot exactly when. One of the times I was talking to you, you were thinking of taking up a personal mission about sharing this news about tires coming off of trucks. You had some alarming statistics on that.

Three truck wheels fall off in the United States every day, and one in Canada. The industry has gotten smart enough to put 550 foot-pounds on every M20 lug nut on every eighteen-wheeler. The problem is, if you’re in San Diego, like my friend Carmen, the K-factor is very different than if you’re sitting, like Eric and I, in northern Ohio. They know that that number makes no sense. Five hundred fifty foot-pounds on every M20 lug nut doesn’t give you consistent results.

Three truck wheels fall off in the U.S. every day and one in Canada, but the industry’s gotten smart enough to torque every M20 lug nut on every 18-wheeler to 550 foot-pounds. Share on XWhat happens? They said, “Let’s use two drops of oil on every lug nut before we put it on.” That’s a little vague. The people here in Cleveland figure out, “That’s probably not enough, so I’m going to bump it to 650 foot-pounds,” or “I’m going to do a three count on my impact gun instead of a two count.” They love to call them ugga-duggas. It is two ugga-duggas on my impact gun instead of three, or something along those lines. What they’re actually doing, since lug nuts are reused bolts, we do not want to take those into yield. Imagine if you’re taking the lug into yield. The third time you install that lug nut on that same lug, you’ve yielded it.

You hit the point where it’s yielded, or gone into the plastic phase, where it doesn’t come back. It’s no longer an elastic spring. It’s plastic like your old slinky that you used to pull apart. Once you hit that point, you could potentially shear that bolt or take it to a point where the first time you hit a bump, you’re going to shear that bolt. The wheel is going to keep that bolt in place. You don’t know that you now have nine lugs doing the work designed for ten.

It’s my opinion that eventually, you get to the point where it cascades. You’ve got seven good lugs. All of a sudden, you hit a bump. The wheel goes flying down the road. Unfortunately, that industry is currently trying to figure out how to make it so that the nuts aren’t backing off of the lugs, which, in my opinion, isn’t really a problem to begin with. They’re over-tightening their bolts, not under-tightening their bolts. I can get off my soapbox.

Since you brought this to my attention, I haven’t driven down the highway with the same thinking. I put the gas on every time I pass a truck.

I always look and make sure that the wheel’s not wobbling because it’s an issue. Someday, they’re going to address it, but it’s probably such a huge liability that everyone is a little bit scared to be the first one to realize it.

Since I learned about this statistic, and I’ll tell you how I learned about it in a minute, I always tell my kids and my wife, “Don’t dwell around semi-trucks when you’re on the freeway.” I’ve been in the plants and seen some of their bolting practices on other parts of the truck, so don’t dwell around semi-trucks on the freeway. Many years ago, we started the Fastener Training Institute’s Certified Fastener Specialist Program, back in the day when Joe Greenslade, Bengt Blendulf, and I were doing it in the ’90s. One day, Joe Greenslade would always show up with the Skidmore-Wilhelm, an indicating torque wrench, and a clicker.

He pretty much always had that equipment in his trunk, didn’t he?

He did.

I think he slept with it.

It was a small Skidmore. A Model P, is that what the small one is called?

That is the small one, yes.

It’s the pocket version, John?

That’s right.

Joe would do a torque tension demonstration. If you’ve never seen it, it’s a real light bulb moment. That’s why I love doing this training for people. We would change something in the joint. We would use a soft washer instead of a hard washer. We would add some lubrication. We would say, “This is a brand new, fresh nut and bolt. We’re going to tighten it. What happens on the second time or the third time?” There are all kinds of variables you could throw into the equation to learn what happens during that tightening process.

One day, at the end of one of these sessions in Los Angeles, Joe Greenslade hands me the torque wrench and the box with the Skidmore. He said, “This is yours. I’m done with this.” He retired from it. I took over. I was doing it from then on for several years. Along came the opportunity to have John present it. I thought, “This is great. We got the Skidmore man himself. He’s going to come and give this presentation.” He did a great job. We loved having him.

He had a Skidmore that had a pressure transducer attached to it, so he could throw up on the screen what was going on on that little dial that you can’t see from the back of the classroom. It was freaking awesome. One of the things I rail about is people saying fasteners are the most dangerous things on the planet. They are not. They’re statistically amongst the safest technologies we have. They are probably safer than drugs, safer than food, safer than a lot of things, and safer than guns.

Fasteners are amazingly reliable things, statistically. They are also amazingly forgiving. You have to mess up pretty damn bad to make a fastener fail. Not that we have not had fastener failures causing catastrophic things, deaths, and so on. By and large, not very damn many. I was telling this story. I said, “It’s not like the wheels are coming off the wagon all over the place around the country.” John puts his finger up and goes, “Just a minute, Carmen.” He told me that statistic. I thought, “I won’t use that line anymore.”

Fasteners are amazingly reliable and forgiving—you have to mess up pretty bad to make one fail. Share on XWhen you think about it, three out of how many million trucks are on the road doesn’t sound that dramatic. If you’ve ever seen a video of a wheel that came off flying down the road, it’s a death trap. It’s not something you want to mess with.

Imagine that thing bouncing down the freeway like a basketball and landing in your windshield.

It’s amazing. A lot of fasteners aren’t used in industries where they make that big of a difference. The fastener that holds your doorknob on your door, if it fails, no big deal. You might have to get a locksmith to replace it or something along those lines. In a lot of industries, it’s critical. Wheels are one of them, bridges, skyscrapers, and all that stuff. It’s important.

We’ve talked about aerospace a lot on the show. Fasteners are an extremely critical part of all of these fields.

Aerospace Insights: A Simple Demo’s Profound Impact

I have a great story about aerospace. I got a call. We had just bought the company. Carmen Vertullo is a godsend to me because I learned a lot from him from the very beginning when we started taking over. I’ve fortunately had some good people around me to teach me this stuff because I didn’t know it when we bought the company.

Refresh our memory, though, before you get into that. What year was that that you took over the helm over there?

We bought it in 2006 from John Wilhelm, who was the founder’s son who had taken over the Skidmores. The Wilhelms had parted ways, but John Wilhelm was still running the business. We bought it directly from him.

Let’s circle back to that history after you tell us this piece.

Sounds great. I get this call. I’m a relative newbie. I’ve figured out the torque tension relationship. I figured out my demonstration skills pretty well. This is before we had the virtual gauge. We had to get up in front of a room. I got invited to an aerospace company on the West Coast that did a lot of space shuttle work. I go up and do my demo. My demo is simple. I take a model P. It’s a 3/8- inch bolt. I tighten it with a certain amount of torque. I take the nut off. I put cherry ChapStick or sometimes strawberry ChapStick, if I can’t find cherry ChapStick on the face of the nut. I’ll use the same torque. I’ll tighten the same bolt. I’ll get a 300% increase in load.

Just adding a little bit of lubrication to the face of the nut dramatically changes that torque tension relationship or K-factor, like you called it. I was in a room in front of literal rocket scientists. I did this demo. I had about another 45 minutes to go. Honestly, I did the demo. Their jaws dropped, which amazed me because these were rocket engineers. I didn’t get another word in for the rest of the meeting.

After about five minutes of them going back and forth, I just sat down and let them go. It was the easiest demonstration I have ever done. My part was five minutes. It was in front of these rocket guys. They take off that simple knowledge, that a-ha moment. That 30-second demo completely changed how they looked at what they were doing. This was a company that was successfully making space shuttle stuff. It’s amazing to me, the knowledge that you can impart just by a simple tool.

It's amazing how much knowledge you can impart with just a simple tool. Share on XIt really is. Your enthusiasm for all this very much shows through. Before I got to know you, I was at the Brighton-Best in their Cleveland facility, where we did the fastener training. In their quality lab, you had yourself set up. You did a demo for us. There were a lot of eyes opened during that. I could tell you were just enjoying that. You did a great job of explaining all this, then at a remedial level, I might add.

I love teaching classes. It was funny because we had developed that Model P. It was basically developed for me to do demos. Kenny Waugh with IMPACT has been very instrumental in our company here. He is a former ironworker who now works for the ironworkers, the Labor Management Group. He invited me to come speak at the first-ever IMPACT Labor Management Conference in Orlando back in the day. It was great because I like to say Mr. Skidmore, Mr. Wilhelm, I, and my partner, Dave, showed up. We’re high school buddies, if you can believe it. We met on the first day of fifth grade. We show up at this meeting. I’ve got a table. At the time, I had a little tent with the Skidmore logo on it.

We were there with Ford Motor Company, Lincoln Electric, and two other huge companies. Dave and I were standing there at this meeting. I got to teach a class. I went right after Greg Gumbel, who unfortunately passed away. He did a presentation. I was next. It was in front of 700 people. Fortunately, I had the demo unit. I had it on a big screen. In fact, they had three or four big screens. I did my demo. It was the same thing.

I got the biggest kick out of these people who have been bolting for 40 years. They had never seen the difference in lubrication on a bolt. Light bulbs went off. I’m proud to say that because of those meetings in those teaching segments, the model P is now our number two selling unit. Every Snap-On tool training center in the US buys one to teach young budding mechanics and aerospace guys the proper torque tension relationship training. We sell a whole lot of those Model P’s now. I’m pretty proud of that.

The Chapstick Revolution: Unexpected Lubrication Solutions

I hope you also have a line of very overpriced ChapStick that you have branded.

It’s funny. The reason I used to use Castrol stick wax, and it was actually the IFI meetings that people would come up to the trainings that Carmen used to do, people would come up to me afterward and say, “What’s that Castrol stick wax? I got to get some of that.” In my mind, they were missing the point completely. It wasn’t the fact that I had this stick wax that made it easier to put your bolts in. It was that you need to know the condition of your bolts and the lubrication within the bolt, so that you know that you’re properly tightening the bolt. I started to use something as ridiculous as ChapStick. It worked. Everyone laughs.

I have to tell you another funny story since we’re talking about it. I did get a call from rural Maine. I believe they were putting up wind towers in rural Maine. The guy called me. He didn’t have enough power on his torque wrench to tighten the bolts. Wind towers use pretty big bolts. He’s talking M36 to 64 bolts. You need a lot of torque to get those going. He had lost his lubricity. I said, “Just get some stick wax.”

He goes, “Where am I going to get stick wax? I’m in the middle of the woods. I got to put these in today.” I said, “Is there a drug store? Can you go get ChapStick?” He said, “Yes.” There are some wind towers in rural Maine that were installed because ChapStick was put on the face of the nut. He bought the store out of ChapStick and installed their nuts on their bolts using ChapStick. It can work.

I don’t know if you know this or not, Carmen, or if you noticed. Buckeye Fasteners, I don’t know if they had it at Fastener Fair. They definitely had it at the Vegas show, a big keg of old rusty bolt, their beer. They switched over from the old rusty, and now they have ChapStick. They downshifted a little bit, but now you’re giving me an idea. Maybe we should meet up. John, you don’t attend the trade shows, do you? I don’t know that I’ve ever seen you there.

I went to a few of the trade shows, the Las Vegas shows. Typically, for me, to make it worth our while, we need to be presenting something. Nobody wants to see me present every year after year. Usually, I will go when I can present. On the flip side, in structural steel, we’re at most of the trade shows. We go to the steel show every year. I do the Labor Management Conference with the ironworkers every year. We do the train-the-trainer sessions in Ann Arbor with the Ironworkers International. I do a lot of trade shows. Fortunately, I’m old enough that I can decide which ones I can go to. We’ve dropped the wind power shows. If I’m ever invited to speak, I’d love to go out there.

You know your business.

The Plumber’s Secret: Toilet Bowl Ring Wax As Lubricant

I let this cat out of the bag a while back on this discovery that we made. We had a very similar situation where someone had a way to do a PIV test. We did it on the tailgate of a truck with a Skidmore. They rented this high-powered torque wrench. These weren’t big. These were maybe 1 1/4-inch A325s, hot-dip galvanized. The torque wrench they had, which was electric, was not powerful enough. I said, “We’re going to have to get some better lube.” You’re allowed to lube them on the job site.

We had two choices that I knew of. One was Johnson’s floor wax in a can, which is about $20. It’s nasty. It smells bad. It’s sticky and not fun. The other one was TBRW. I brought both to the job site. I let them choose between the two of them. I didn’t use to tell people what TBRW was. It’s been a closely held secret for many years. I believe at one time, I was doing a Fastener Training Minute. I said, “I’ll be at the show. If you want to know what TBRW is, come to my exhibit. I will show you. I will give you some.” I’m going to let the cat out of the bag again. Here, TBRW is toilet bowl ring wax.

If that town had had a hardware store instead of a drugstore, you could have gone down there and gotten a toilet bowl ring for about $1, maybe $1.25 now. It’s the cheapest wax you’ll ever have. Matter of fact, we had a situation where we needed to use it to get some bolts to pass a ROCAP test here at our lab. If you use the wax to pass the ROCAP or the PIV, then you have to use the same wax in the steel when you do the erection of the building. They had thousands of bolts.

They said, “What are we going to do?” I said, “Go to Home Depot. They’re $10 for a case of them. They’re super cheap.” They’re easy to use. It wipes off your hands. It doesn’t smell at all. There’s no odor to it. If you get it in your mouth, you won’t throw up. It has a wonderful consistency to it. It’s softer than the stick wax. It’s maybe about the same as ChapStick, which also smells good. If you get it in your mouth, you won’t throw up. It’s very expensive.

It is, relatively speaking. That’s great. The plumbers of the world know that.

I thought I should go buy cases of TBRW and just melt them down into a paint can and sell them as bolt wax.

That looks like something that you could do at your facility out there, John. You had a paint thing going when we were there. You were doing a side gig.

We do have a business that makes a unit that fills aerosol spray paint cans with custom color paint.

That was it.

It’s just a pump. You pour somebody’s paint into the reservoir. You put a can underneath. You close the door. We’ll put the paint in the can. It’s a tiny little business, but again, we like our little niches. We’re the only ones who make it in the world. I sell that thing all over the world. It’s still small. When you need John Deere Green in a can, and you go to your favorite paint store, odds are they’re using one of our pumps to pump it into a can.

Like I was saying, it’s like a mad scientist’s den over there.

My partner and I might have mentioned, we met on the first day of fifth grade. We were both new to the school district, Orange High. Go Lions. We sat at what I can refer to as the nerd table because everyone else knew each other. It was a very small school district. They had grown up together. We were the two outsiders. We sat at the same table and struck up a conversation. Here we are. That was 1976. Here we are, so many years later, owning businesses together. Dave came up with the idea that we should buy companies from guys who want to retire and whose kids have left Cleveland. That’s what we started doing.

I actually spent some time in San Diego. I owned a glow-in-the-dark driving range in Carlsbad, California. That’s where I met my now wife. It was the greatest day ever. Once summer was over and kids started going back to school, the driving range business dried up. I went back to Cleveland. She was nice enough to join me. We were married within six months and moved back to Cleveland. That’s when Dave and I started looking for these businesses to buy.

It’s a great story.

We’ve got a bunch of them. We brought on another partner, Wendy Wloszek, who is our Head of Operations. It’s a nice little team.

Dig back then. Tell me the story about how the company first got started. That’s a tale unto itself.

That’s a great story. That comes from John Wilhelm, who is one of the greatest guys. He was very generous in selling us this business. He was looking out for the employees. He was ready to retire. He didn’t want one of the bigger companies to come in from out of town and close it down and move. He was loyal to his employees. We were actually in the building. He tells the story of the foundation. His mother, who was probably 5 feet tall and maybe 85 pounds when I met her, helped pour the foundation of the building we were in when we originally bought the company. We have since moved.

His mom and dad lived in Euclid, Ohio. They’re walking down the street. They see somebody’s house. Their basement looks like it’s on fire. They go knock on the door. Lo and behold, it was Dick Skidmore. It wasn’t on fire. He was an engineer with Lincoln Electric, designing welding equipment. This is back in the ’40s, probably right after the war, I’m guessing. They struck up a conversation and a friendship. A few years later, they decided to open a machine shop together. The families actually lived together in the same apartment to save money so that they could get this business off the ground. It’s one of those stories that you just can’t believe until you hear it that they met because of a happy accident.

Somebody thought somebody was saving their house. It turns out Dick Skidmore was quite the inventor. He was the guy that they came to about five years later to invent this. We still have machines. We do machine stuff for other people. The lion’s share of our business is the Skidmore product line that he invented over the weekend. It’s just expanded from there. We sell all over the world, every continent except Antarctica. There may be one there, too. I don’t know. I haven’t sold it directly to them. We sell everywhere. About 30% of our business still goes outside of the US. It’s amazing that this company started way back when. It’s still clicking right along.

It is an amazing story. We started off with another amazing story about Mel Kirsner and the Fastener Museum. I have a little bit of data on that here if I can share it. He started the museum in the mid-’90s. I don’t know how many years it took him to build it. It burned in 2003, in October. I can’t remember the name of the fire, but it’s a famous Southern California fire. Lots of property was lost. Mel passed away at the age of 77 in November 2008. He’s remembered by lots of memorial stuff online, as well as the Pac-West Memorial Golf Tournament, the Mel Kirsner Golf Tournament. I believe someone is trying to establish an online fastener museum that will include lots of his legacy.

That’s interesting. That’s good to hear. We’ll have to get our arms around that. You hear rumblings about it. I was talking with Gary Graham from out here in Cleveland some time ago. In his travels, he was aware of an old Porteus semi-trailer that was parked somewhere and had the original paint job on it. It looked very old-timey and retro. He was floating the idea that, “How about we pile all of this memorabilia, as much as we could, into one of these semis, make it into a mobile museum, and drive it around to all these fastener events?” I thought that was a pretty cool idea.

That’s a really cool idea.

That sounds like an idea for a segment, Eric.

Sounds like an idea that comes up in a late-night fastener bar setting.

You just have to find the right person to take it in or run with it.

Somebody’s got to be crazy enough. One of you guys who makes $100 million selling your company is just twiddling your thumbs. Why don’t you jump on this?

Absolutely.

John, I generally exhibit at the IFE in Las Vegas and also at Fastener Fair in Nashville. I will bring something with me to that show, that’s a hands-on demo. We actually brought a hardness tester and a tensile frame. I have a very nice little stand with an I-beam on it that we can mount a Skidmore on. If you want to go to either of these shows, and we can do the show floor auditorium training with the Skidmore, I would be happy to set that up. You just have to show up.

In May, we’ll be in Nashville at Fastener Fair.

I absolutely love Nashville, so I’d be thrilled to be invited to that. You’ve invited me to other ones like that. They always go very well. They’re well received, so count me in.

The constraint that I have is the Fastener Fair in Nashville. It’ll be fine. It’s right before the Hydrogen Embrittlement Conference. There’s the underover. I don’t know what that is. It is in France, the first week of June. If I go to Fastener Fair, and I’ll be there based on this, I’ll be flying right out of Nashville to France. I’m sure you can get a ticket from Nashville to France.

I would think. You might have a few jumps, but you can get there.

I’m going to work on that.

We’re on the fly fastener calendar planning here with Fully Threaded Radio. We’ve covered a lot of ground here. Any other stories you guys want to bring up? I know you’re full of them.

I’ve got great stories.

Stadium Construction Challenges: Heat, Lubrication, and Bolt Failure

Just dive into one. Let’s throw one more out there before we wind this one up because I know you guys have so much to say. Sometimes, it’s like standing on the edge. Where do you jump?

Another one of my favorites is there’s a very famous football team. I won’t mention who they are, but they’re building their new stadium. We get a call from the guys putting it up. They’re using tension control bolts. It’s 120 degrees on the field. These bolts are sitting in the sun. They don’t understand why their tension control bolts are actually shearing in tension, which means the threads are giving way. They’re pulling the bolt apart. The spline never breaks off.

I was laughing. I said, “Do you think that lubrication has become way too efficient on those bolts?” They said, “What are you talking about? Something has got to be wrong with the Skidmore, right?” I said, “I don’t think so, but why don’t you take everything, put it in the trailer overnight, temperature-controlled, and test it the next day? Let me know.” Believe it or not, I’ve never heard from them again, but I know that this stadium is standing. I’ve seen a few ball games done on it. It’s truly amazing to me that the guys are doing this day in and day out. Something as simple as the quality of the lubrication on a bolt that requires lubrication is critical to installing the bolts. It’s not the first thing that hits their mind.

We’re working with the ironworkers to get a lot more training on bolts. It all steered out of that. I’m only one guy, so I can’t do all these training sessions, so we put together an online training course. If anyone is interested, they can certainly reach out to us. We’ll hook them up for some free training. We do certify people. We charge for that, but you can learn a whole lot about bolt torque tension by watching the videos that we’ve put up on our website, Skidmore-Training.com.

There’s a whole lot of free information there that we try and support, but we also want to be a resource where, if somebody is willing to put in the time to actually learn it and take some tests about what they learned, they can get certified. It’s directed towards structural bolting. We are about to get accredited by, hopefully, the Ironworkers Labor Management Conference. People will be able to get CE credits for taking our class online. We think that’s a good tenth step. We’ve taken the first nine. The next step is to get people to want to do it and give them some incentive to do it. We think CE credits are one way to do it.

That’s the endorsement that you need. I would also say that you should strive to make Skidmore-Wilhelm the official torque tensioning device of the NFL.

Yes, absolutely. I tend not to give names because no one wants to be associated with a project that we hear about when things are going wrong.

I’m in favor of all that. It adds drama to the segment, so fire away if you can. I know it’s not Minnesota because you said it was 120 degrees, so I’m guessing it’s somewhere down south.

You can figure it out.

What was their season?

Big screens, that’s all I’m going to say.

I have a story for you, Eric. Before I do that, John, let’s collaborate a little bit because I love bolting training. I prefer the in-person, hands-on, do it in my lab training. If there’s a way to bring what you have into the lab, or even take it on the road in a live venue somewhere, let’s think about how to do that.

I’d love it because the one piece we’re missing with our online training is the hands-on. Doing a lot of ironworker training as I do, I spend about 30 minutes in the classroom and 1.5 hours in the shop, actually getting these guys and girls to tighten bolts. There are a lot of females joining the ironworker ranks these days, which is fantastic. The light bulbs go off when they tighten a bolt, and something goes wrong. They don’t hit the tension that they need. There’s a reason behind it, so let’s figure out what the reason is.

What time investment would you say is adequate for a solid background in this field, John?

I would say 2.5 hours of a combination of classroom and hands-on.

We’re going to agree to disagree on that, John, because it’s more like two and a half days. We’ll talk about that later. A different story comes to mind because of what you just said about the ladies. At the NFDA meeting here in San Diego, we had this cool fishing trip. I did a lab tour. We cooked the fish during the lab tour. It was great.

What batter did you use, Carm?

It was Eric Dudas’ special formula.

It was my recipe, wasn’t it?

I don’t get that.

It’s a special feeling. It wasn’t like we went out, shot a deer, and ate it. We caught these fish on the bottom of the ocean, brought them home, and made fish tacos out of them. They were the best. We’ll do that again, by the way. However, the next day, we had the lab tour. Lots of people from the NFDA were there. I was pleased that the BBI owners, Jun and Peggy, were there. I was demonstrating the Skidmore-Wilhelm Bolt Tension Calibrator, doing the PIV test of some tension control bolts. There were also a lot of other ladies.

If there was a lady in the group, I tried to encourage them to come up and set the tension control bolt, because I said, “There are very few female ironworkers. If you’re not an ironworker, chances are you’ve never even seen this, let alone done it. You’d be a rare person, being a female, to come up here and set the TC bolt.” They almost always did it. The shear wrench, the special wrench you do this with, is heavy. There’s another wrench you have to use to get it out, which we call Black Beauty. It’s a big honking impact wrench. It sounds like a cannon going off when you use it.

The next group had Jun and Peggy. I tried to get them to come up. They wouldn’t do it. I said, “Wait a minute. You sell bucket loads, container loads of these bolts all around the world. Have you ever set one of these things?” Neither one of them said they had. I shamed Peggy into coming up and setting the TC bolt. It was great. First time she had ever done it, she says, “Now, I know how it works.” That was fun. I feared that it would have been embarrassing to me if neither one of them had decided to do it, so I’m so glad. If you read this, Peggy, thank you so much. It was a hoot.

I’m going to go to a more serious story, my very first foray into having a problem to solve on the job site using the Skidmore. It turns out, in this case, the problem was the Skidmore. I hesitate to say this because John is here, but people need to know about this rare but peculiar problem that can happen when the Skidmore is not properly maintained.

A Peculiar Problem: When The Skidmore Itself Fails

Fire away, Carm, because folks have come to depend on Fully Threaded to give it to them straight.

This is a straight story. Many years ago, I got a call. I’m going to say all the names now because it’s been long enough that it doesn’t matter. I get a call from Mark Cordova. Everyone knows who Mark is.

Mark is great.

He was at Cordova Bolt at the time. He said, “Carmen, there’s a job in San Diego at Mesa Community College. It’s the Mesa College Math Building they’re building. They’ve rejected nine lots of TC Bolts that I sold them. The job is shut down. They’re having a panic. They want to remove all the bolts. They have a concrete pour on the fourth floor, and the third floor tomorrow or Monday.” This was Thursday. “Everybody is crapping their pants. Get over there.” I said, “What am I going to do?” He said, “We need to probably get a Skidmore.”

I said, “I’ll try to get one.” He said, “I have one.” He’s got a Skidmore. “I’m going to drive it down in the car right now.” He comes down. This is Thursday. He’s there midday Thursday. He’s got a Skidmore. It’s not calibrated. We can’t show up on the job site with a Skidmore that’s not calibrated. I find a Cal Lab that can calibrate the Skidmore that day. I pick it up the next morning on the way to the job site. I get to the job site. I go to the trailer of the erector.

This guy, his head is coming off. Big John, I can’t remember his last name. Herrick Steel was the company. John is now a retired, famous guy over there. He was threatened with a restraining order by the inspector trailer because he’s going to tear them apart. It is because he knows there’s no way in hell that nine lots of TC bolts can be bad. That’s the first clue, by the way. When someone has multiple TC bolts that aren’t performing the PIV, it’s probably their process or the Skidmore, maybe.

In this case, the TC bolts were all pulling very low and exactly the same. This company had twenty Skidmores. This was an inspection company. They had one that was always set up to pull just 7/8. They kept the 7/8 plate on it. That’s a luxury, by the way, to be able to keep your Skidmore just with one size. I looked at their Skidmore. I had our Skidmore. We had all the plates and everything. I noticed that they were using spacers for bolts that weren’t that long. The reason they were using spacers was because installed in the Skidmore were plates that are known as short pressure plates. You only use those when you have very short bolts.

There are two lengths for which you need the short plate. By the way, when the bolts are even too short for the Skidmore, there’s a test you can do just in the steel without the Skidmore, but that’s another story. I said, “Have you examined these plates?” They don’t know anything about the plates. They’ve never changed them. They were using these short plates with every length of bolt with spacers for years. The short plates, by virtue of being short, have thinner metal in them.

If you abuse them year after year after year, they can bow. That little bit of bowing will result in the back plate and the front plate coming into contact when you tighten the bolt. It prevents the hydraulic pressure from increasing in the Skidmore. What we did was we put my Skidmore. We had Skidmores at the O.K. Corral. I do have video and photos on this. There are two Skidmores on an I-beam. One had to be upside down because we had them both on the same side of the I-beam. We swapped plates.

We put my plate on their Skidmore, and the bolts passed. We put their plate on my Skidmore, and the bolts failed. I took that plate. I put it on a flat surface, which was the green box, where the Skidmore came in. I spun it like a top. You can put something that is a flat edge, like a ruler, across the back of it, and you’ll notice it’s bowed a little bit. That’s how you indicate that. As we were doing this test, one of the things that creeped me out was that there were just a few people there, and then all of a sudden, there were more people. There were men in suits. There were women in skirts. The building owner was the dean of the school or something having to do with the San Diego Community College District.

She was a woman. This was a very important problem because they had the job shut down. They had a cement pour scheduled for the top floor on Monday. This was Friday afternoon. My client was the bolt supplier, not Herrick Steel. My client was Cordova Bolt. When I went into the inspector’s trailer, they hardly paid any attention to me. I had to get their attention. I said, “I’m here to solve your problem. I represent the bolt supplier, not Herrick Steel. We can get this fixed if you’ll give me some help.” They did. We made this agreement on Thursday to show up on Friday and do this test. The problem went away.

We got notice that the bolts are fine, but the mistake they made was this. Herrick did their PIV test as they were supposed to before they ever installed any of this bolting. They did the PIV test. They had the records. They invited the special inspector to witness the test. The special inspector either didn’t get the invitation or declined, but didn’t see it, and insisted on doing their own. When they went to do their own, they had this failure.

It’s probably pretty rare that you actually have a PIV test where you invite the special inspector and they choose not to show. I will tell you, as the erector, when you do your PIV test, if the inspector chooses not to attend, you make sure you have a record of that and email something that you can prove that they were invited and did not show up. Herrick should not have even let them do that test because that was not a requirement of the contract to have a secondary test. The test was done properly when it was supposed to be done. They had a record of it. Those bolts passed.

That’s one of the rare things that can happen when the Skidmore is not properly maintained. I don’t know how many times you would have to abuse the Skidmore, tightening long bolts in a short plate for that to happen. Clearly, it’s been thousands of times over the years because those plates had not been taken off that machine in anybody’s memory. That was my very first job site where I had to show up and solve a problem. It went spectacularly well. I tell that story almost in every structural bolt training that we give.

That’s a great one. It’s funny. I can give you a little bit of history behind the short bolt plates. The original Skidmore unit was a Model M. That’s the one I have the serial number 102 back in my plant. Bolts were starting to get shorter. Our Engineering Department developed the Model MS. The S stood for shorter bolt. Similarly, there was an H, and now, there’s the HS, which Carmen has. That’s for short bolts as well. Bolts got even shorter.

Our engineer said, “Because of the laws of physics, to test shorter bolts, we either need to make a much bigger Skidmore unit, which has to be much taller and wider, or we can create what we call short bolt plates. We sell them with the caveat that these plates and bushings will survive tens of thousands of tests, but eventually, we know that the middle is so thin. Based on the load you’re putting on these plates and bushings, they can warp, and they will need to be replaced. The easy way to see it is by putting it on a flat table. They wobble.” To this day, we still get people who don’t quite understand that. They wonder why.

You can test as long as you want, even if you’re using the short bolt plate, but it’s not a great idea, especially if you test a lot of bolts, because eventually, you’re going to wear that thing out. Exactly what happened to Carmen is going to happen to you. The plate and the bushing are only a fraction of an inch apart when we create the load in the Skidmore. If they bend at all and they start touching, they’re not going to go anywhere. You’re just going to break the bolt or not achieve any load in the Skidmore.

The short bolts, where you need the short plates for, as far as testing, are the vast minority. It doesn’t happen less than 20% of the time. Make sure you only use the short plate for the short bolts, and they’ll last forever.

They will last forever. We’ve never had one of those warps.

I would imagine that folks who are reading this part of the conversation are really into the particular subject of torque tension testing and the nuances of it because we covered a lot of the juicier parts at the top of the conversation, and dug in here as we’ve progressed, which is fine. At this point, we probably want to take a look and see if there’s anything coming down the road that we can advise people of and wrap it up from there.

The Future Of Bolting: Stainless Steel Standards And Training

Structural bolting-wise, I have some very good news. The AISC and the RCSC have completed the new guide for high-strength stainless steel structural bolting. We’ll be seeing that soon. I will be doing lots of testing here at Carver Labs because ASTM is also in the process of developing a standard for high-strength stainless steel structural bolting, which is more commonly used in Europe. They know a lot more about it than we do.

Some people in Europe, Nancy Badeau, particularly in London, and Jason Provines at the University of Virginia, are working on that. I got to head up the RCSC Oversight Committee. We’re reviewing that standard. It should be done. We are reviewing it, and then it should get published. Stainless steel is a peculiar animal. There are a lot of things that make it more difficult to work with than steel, but people want to build stuff out of stainless steel, so it’s necessary. Look forward to that.

Stainless steel is a peculiar animal—it’s more difficult to work with than steel, but people want to build with it, so it’s necessary. Share on XFrom my end, the good news is there’s no news. I would encourage people who want to learn more about this topic. We sell a lot of equipment, but as Carmen said, I have a passion for teaching people about torque tension. We have a separate company doing the training. We are actively going to job sites. It’s fortunately not me because I’m old enough, and my kids are still in the house. I don’t have to go to all these places all the time. I get to pick and choose when I go.

You’ve got people, John.

I’ve got people to do that. We are doing a lot of training almost every week. He was in rural New York. He’s going to Columbus, Ohio. That’s good news. Whenever anyone contacts us about training, it’s usually because there was an issue or they realized they didn’t know what they were coming up against. We get fun stories all the time. The Florida DOT now requires anyone who’s putting up those big street signs that are going up over highways in Florida to be certified by our online training program. Unbeknownst to us, they just declared it.

They took the class. We probably gave it to them for free. They took the class and said, “Any steel erector has to go through this before we let them put structures over our highways, because you can imagine the liability of those signs coming down.” I’m extremely encouraged. Every time I see John Wilhelm, he smiles at me and says, “At some point, we thought we would sell all the Skidmores that needed to be sold. This company keeps plugging along. It’s because of people wanting to do better.” That’s encouraging to me. The fact that they’re willing to take the time to do the training and tune in to your show is encouraging. It’s excellent.

Training And Certification: Empowering Fastener Professionals

We’re speaking primarily to fastener distributors and also probably a handful of fastener manufacturers or people who are involved in it. Do you do much training that is specific to their quality assurance facilities, for those technicians working there?

We have, and we will, anytime they contact us. We don’t proactively look for those situations because they usually fall on deaf ears. I try and do them as often as I can. I was thrilled, Carmen, when, back in the day, you invited me to do the Monday session. Every Fastener Training Week, Carmen would give me Monday afternoon. I would come and do my little dog and pony. I would get a lot of training sessions out of that.

People were interested in that. We weren’t selling a lot of equipment, but that wasn’t the point. The point was, “You need to know what’s going on when your customer calls and they’re having a problem.” I’m thrilled to do those things. It’s frankly free. If it’s too much expense, I might ask you to share in my travel costs, but we would love to come out and do any hands-on training that anyone wants.

Fire that contact info out there again, please, John.

I’m John O’Brien, Skidmore-Wilhelm.com. My email is JOBrien@Skidmore-Training.com.

You’re still out there, Carm. What do you have to say to wrap this up?

My wind down is, John, you and your beautiful wife have to come out here to San Diego. I know she loves the area.

She’s a native.

We’ll do one of those training programs in our lab here. I have lots of people who are begging me to do it. Distributors, that job site I was on, every bolting guy there said, “We need this bad.” Let’s make sure that happens.

That’s excellent.

My only request is to time it for some time when there’s a good bite out there off the coast. I’ll come, too. We’ll catch some fish and fry them up.

My request is to do it when it’s cold here. I can come out and visit San Diego and get a week of warmth in.

We’re going to do clinics. The clinics will be something like a half day, but we are also going to do a two-and-a-half-day program that is called Infrastructure Fastening, where it’s not just structural bolting. We’ll do large bolts, embeds, self-drilling screws, and all the things that go into putting a building together.

Fascinating. It sounds great.

We’ve been talking with John O’Brien. He’s the Skidmore-Wilhelm guy. I hope you’ve enjoyed reading some of the background on that, in case you were unaware. Carmen Vertullo is a longtime friend of the show. I sure do appreciate you being here, guys. I know we’ll be hearing from you in the future.

Thanks, Eric. I look forward to seeing you both soon.

Thanks. We’ll see you around.