The new fastener year begins with dramatic headlines, Fastener Technology International editor in chief Mike McNulty breaks the stories and welcomes Huyett CEO Tim O’Keeffe to look at complete 2024 FDI numbers plus the outlook for the year ahead on the Fastener News Report. EXTRA: Star Stainless president Tim Roberto Jr. explains the latest huge LSG acquisition. On the Fastener Training Minute, thread guru Carmen Vertullo looks at risk mitigation in structural bolt tensioning. Plus, Fastener Fair USA show manager Blanca Delgado previews the upcoming event in Nashville. Brian and Eric often work independently, but sometimes they join forces, and when they do, it can mean fastener podcast gold. Run time: 01:19:51

—

Listen to the podcast here

Important Links

- Tim O’Keeffe on LinkedIn

- Mike McNulty on LinkedIn

- Carmen Vertullo on LinkedIn

- Tim Roberto Jr.

- Blanca Delgado on LinkedIn

- Fastener Fair USA

- Huyett Blog

- Another Way: Building Companies That Last…and Last…and Last

- The Great Game of Business

- Tommy O’Keeffe on YouTube

- FDI Survey

- Fastener Technology International

- Fully Threaded Radio Email

- Mike McNulty Email

When We Do

What’s In This Episode

I’ve got a great episode lined up for you. Once again, we’re going to keep it a little shorter than we used to do, but it’s jam-packed. This is Episode 208 of the show and we’ll drop this one January 17th, 2025. Getting used to the sound of that already. 2025 is already off to a dramatic start. Lots of headlines are already breaking. On the Fastener News Report. Mike McNulty’s got Huyett President Tim O’Keeffe. They’ll start by looking over our shoulder at 2024 as we receive the final FDI report for the year.

We got the whole thing lined up and they do a fair amount of speculating on what’s coming at us, too. Very good discussion. Also, on the News Report, this time, we have a conversation with Star Stainless President Tim Roberto Jr., who will be talking about their latest acquisition. Big Bolt was a big headline to kick off the new year. He’s got a few things to say about that.

Of course, Carmen Vertullo’s got the Fastener Training Minute. This time, he’s going to talk about the risks associated with structural bolting. It can mean a lot of things, but in this case, it means torque tensioning. Carmen’s seen it all over his long career. He’ll share his wisdom with us on the Fastener Training Minute.

We’ll get things kicked off with a visit with Fastener Fair USA manager Blanca Delgado. Fastener Fair’s happening in Nashville in 2025, and it’s right around the corner, May 28th and 29th. She’ll give us a preview. Even though Brian’s not here at the moment, I can speak for him. We’re super excited to launch another season and very glad to have our great lineup of partners backing us all the way.

The title sponsors of Fully Threaded Radio are Star Stainless. Off the shelf, it’s Star. Goebel Fasteners. Quality the first time. Go Goebel. Brighton Best International. Tested. Tried. True. Brighton Best. Fully Threaded is also sponsored by Buckeye Fasteners, BTM Manufacturing, Eurolink Fastener Supply Service, Fastener Technology International, INxSQL Software, Fastener Fair USA, J. Lanfranco, Solution Industries, Volt Industrial Plastics, and Wurth Industry North America.

As always, the email address FTR@FullyThreaded.com. We very much appreciate the comments that you’ve sent our way, especially since we’ve been tweaking the format of the show. I’m not sure how we’ll finally zero this whole thing in, but always appreciate your comments. Before we cut to this conversation with Blanca from Fastener Fair, I’d like to say congratulations to Steve and Cheryl Dunham of Sasco Fasteners up there in Medford, Oregon.

Steve’s been a longtime pal of the show and FCH and actually, I think he was on board either the first or second year that we launched FCH. I used to see him out at the PacWest meetings, and we’ve had him on the show a couple of times over the years. He reached out to let me know that he sold the company. He and Cheryl are finally going to enjoy their long-deserved retirement. They’ve been working about as hard as he possibly could for many years and they’re certainly deserving of it.

When I talked to him on the phone, we agreed to get him on and do a little retrospective. These are the kinds of conversations that I really enjoy. It’s sad to see him go. I’m going to miss him. At the same time, it’s really inspirational for so many in the fastener industry who set off modestly, worked hard for a long time and really achieved the dream. Congratulations to Steve and Cheryl.

When we talk to Steve, which will be in the near future, we can get into the somewhat tenuous feelings that Cheryl developed for the FTR show. I won’t go into that anymore. I’ll leave that as a cliffhanger, but that’ll be something that we can definitely throw in the mix. Have some fun with it. All in good fun, Steve. Thanks for clicking into Fully Threaded Radio. Here’s that conversation with Blanca.

—

Blanca Delgado Previews The Upcoming Fastener Fair USA

It’s bleak, dead of winter here in semi-rural Northeast Ohio. However, Fastener Fair USA is going to be coming up is quicker than we think. That’s happening. May 28th and 29th in Nashville. Fastener Fair Show Manager, Blanca Delgado, is with me now. Blanca, what’s going on?

How are you? Glad to be here.

It’s been a little while. I tell you, while we’ve been warming ourselves up here, getting ready to say what we’re about to say, I am again impressed with the amount of stuff that you actually do. People think you got this time off but in between shows. No way. You never stop. You’re already looking at ‘27.

That’s exactly it.

Show business is not for the faint of heart. Just before we dive into all this again, Fastener Fair coming up the 28th and 29th of May in Nashville. I’ve been looking here at the anti-harassment policy. We’ll work from the outside in. It doesn’t say anything about long hair. You got this long list of things. I’m wondering if you could get that added?

I’ll try to.

You’re always eager to accommodate, Blanca. Fastener Fair will be, I believe, North America’s only fully carpeted fastener event. Is that true?

That is true. We will be carpeted in our aisles. We are giving the choice for exhibitors to carpet or not carpet. There is a big push on the sustainability of carpet. Carpets are only used once. We’re really trying to start being a little bit more conscientious about that. We are giving the choices to the exhibitors to either carpet their space or to always use those stamp-on plastic-y things that are reusable.

That’s a whole other issue, but glad to hear the background on that. We could probably spend a long time on it. Since we only have a few minutes here, let’s dig right in the highlights. The Fastener Fair USA 2025 in Nashville. Everybody seems to really like Nashville, Blanca.

There are a lot of activities to happen. It’s an up-and-coming city. They call it Little Vegas but without the casinos, but enough bars to make everyone happy. We have an exciting lineup of things happening on the show floor, after the event, before the conference even starts. FTI has a really good conference heading up that they’re excited about. I think by the end of the week, you’ll be able to register for that.

The 27th will be the FTI event, and then the 28th is opening doors for the conference. We’re going to have a NASCAR simulator where you can cool you could win tickets to actually go to a NASCAR race. We also have a testing station where you could test different torques of fasteners, how tight things can be without breaking.

We have the networking event happening the 28th, which will take place at the Honky Tonk Bar. Three floors, live music, food, drinks. We’re going to have a few activities. We’re trying to have a make-your-own cowboy hat and ribbons and things like that. We’re pretty excited about it. I’m also working with the Young Fastener Association on a conference for our graduate students that are looking for jobs in the fastener industry.

Is that YFP you’re talking about there?

Yes. Young Fastener Professionals. We’re hoping that that goes through. That’s going to be at the second day of the show, plus a lot of different panels and things like that on in our stage area. We are co-located this year with the Aluminum USA show. That too is exciting because that brings in a lot of folks in the automotive and aerospace visitors that haven’t really attended the fastness show before. We’re expecting a big crowd this year.

It seems like a good chance for crossover in that audience. You’re jamming a lot into this thing.

Yeah. I’m hoping we could jam as much as possible just to give everyone an opportunity to have different sections for whatever they’re looking to accomplish at the show. We’re also going to have a lot of surveys out there, so please, hopefully, our exhibitors and our visitors will be filling those out just to give us a better direction on what they want to see on future shows and how to grow the event.

How does international participation look this year?

We do have a big Taiwan and China pavilion. We have Turkey coming in. We also have the European folks attending. There is a lot of manufacturing. Change in the political climate always gives a lot of options for international growth. That’s our focus on it, to make sure that we have the right exhibitors and attendees attending the events that will support all of that. The aluminum event actually brings in a lot of Europeans and international folks, so you’re going to see a bit more of the international visitors coming in this year.

The political climate always gives a lot of options for international growth. Share on XYou probably have not had a chance to hear the interview that we did with Carmen Vertullo and John O’Brien. He’s with the Skidmore-Wilhelm Company, but they said that they’re bringing on the floor a demo of the Skidmore-Wilhelm equipment too. There’s an added bonus for you, probably something you didn’t know about yet.

I didn’t know that. That’s awesome.

This all sounds great, Blanca. We should also mention that registration is open January 28th, I believe you said, correct?

Yes. January 28th, registration will be open. We will be sending out reminders right before that. Hotel registration is now open. Get your hotel. The links to our hotel housing folks are on our website. Make sure you get that. I know a lot of times there’s a lot of scams going on that people emailing saying that they’re the official. Just know that we only have one official hotel folks and that’s Connection Housing and the information is on our website.

Good to know. The website, once again, folks, FastenerFairUSA.com. Get out there to take advantage of registration starting January 28th. I just want to say, I know we’re going to keep this one pretty tight, but you guys have done such a great job of connecting with all the fastener associations and doing your best to support them, and I hear a lot about that in the background. Just wanted to say thanks for that.

Thank you, guys. You’ve really helped us to know exactly what you want in the conference. It helps us to bring in a better show for the fastener industry. We’re here to support you guys, so it’s really helpful.

Before I let you run, what do you hear from our friend Bob? He’s, of course, the previous show manager and he’s in semi-retirement now or full. What’s the story?

He’s having a great time and doing a lot of vacations, spending a lot of time with his grandkids and his family.

Not traveling.

Not traveling, even though he loves traveling. He’s doing a little bit of that. He is, of course, available. He will be at the Nashville Show walking around, just saying hello to everybody. He misses the industry, so he definitely likes to come back to say hello to everybody.

That’s great. Another reason to get out there, folks. Fastener Fair USA. One last thing, Blanca, getting back to this anti-harassment policy. This is on the website, folks. You can read all about it. FastenerFairUSA.com. What exactly is bathroom policing?

I’m not really sure.

Not going to be doing any of it myself but I just want to make sure.

I don’t think we police the bathrooms. I think that’s it.

That’s good. It doesn’t sound like you want anyone else doing that either. Good thing. That’s what I love about Fastener. Fair. All right, Blanca, well always good to talk to you and we’ll probably get John here one more time before the show, but keep it busy. I know you will.

Okay. Thank you so much.

—

Dramatic Headlines In The Fastener Industry With Mike McNulty

We’ll get on with the news segment of this episode. Big favorite with a lot of readers. Mike McNulty coming up with Tim O’Keeffe. Plus, we’ve got the Tim Roberto Jr. segment jammed in there as well. A couple of items to drop. These flew by right after we got done recording with McNulty. Brighton Best International announces big promotion for our friend George Hunt III, GH III. He’s been promoted to Vice President Sales Industrial North America.

Good job, George. Every time we turn around, you’re getting another accolade. Congratulations on the bump up. Brighton Best International, of course, sporting their new logo for their 100th anniversary, 1995 to 2025. We’ll be talking more about that as the year goes on. I can’t wait to see what festivities Brighton’s got to celebrate that. They’re going to spare no expense, I guarantee you.

The second piece of news I’ll share with you is also a promotion this time from Wurth. Wurth’s been doing some major reorganization and I’m sure we’ll be covering that in greater detail very shortly. This news is connected to that. The announcement, Chapman Revercomb, he’s been elevated to President of Wurth Industry USA.

As I understand it, there are two main operating segments of Wurth now in North America. This is one of them. Chapman’s getting the nod. Congratulations to you. He’s been on the show a couple times. I’m sure we’ll have him back to give us a picture of what he’s going to be doing in this newly formatted organization and his role in it. Way to go, Chapman. 2025 already off to a big start, as we said.

Once again, the Fastener News Report is sponsored by Volt Industrial Plastics and the title sponsors of Fully Threaded, Brighton Best International, Goebel Fasteners and Star Stainless. One more thing. You might remember we had Jake Valdez Davis on with us and he was talking about the return of mud racing to the fastener world. Coming up in August, the Tough Mudders will be hitting the course again and one of our teammates, John “Cool Hand” Butler with Martin’s Supply shared with us he’s got some new fastener-related mud racing ink on his body.

I won’t give too many more details. I plan to do a segment with some of the mud racers very soon and we’ll set that all up for the summer. Do a little recruiting and he’ll give us some details. Cool Hand, you are always blowing my mind. Glad you’re on board with this year’s race, too. Alright, it’s Fastener News time, so I’ll give the preamble. I guess I’m the only one here to do it. Now with news about screws you can use, here’s Mike McNulty.

—

Tim O’Keeffe Explores The Complete 2024 FDI numbers

Thanks, Eric and Brian. This is Mike McNulty from Fastener Technology International Magazine, bringing you the Fastener News Report, which is sponsored by Volt Industrial plastics, makers of the world’s finest plastic fasteners. The new year of 2025 is marching on despite disasters and terrorism. My house and yard are covered in beautiful white snow. Politicians are shuffling in and out of power, and my two favorite college football teams made it to the National Championship game. I am still focused on fasteners and ready to deliver the Fastener News Report.

In this episode, Tim O’Keeffe, Chief Executive Officer at Huyett, joins us to reveal the latest results of the Fastener Distributor Index, also known as the FDI. Also, in this episode, we have our top story on LindFast Solutions Group and Newsmaker Headlines from Bolton, Century Fasteners, Anchor Bolt, Birmingham Fastener, RNS Industrial, Spira, Endries, AFC Industries, Suncor Stainless, Brighton Best International, and more. On the Back Page Report, we’re going to talk about signposts on the Wisdom Trail.

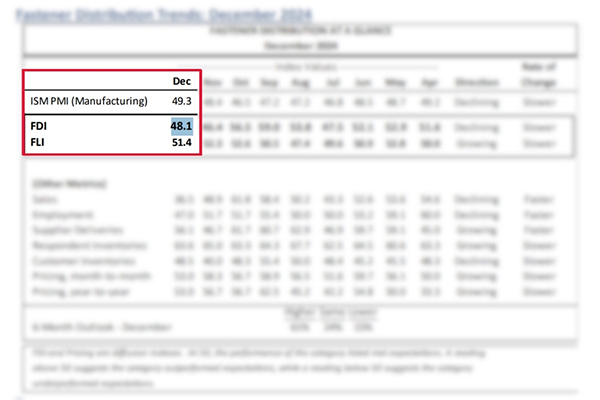

The seasonally adjusted Fastener Distributor Index for December 2024 moves slightly higher to 48.1 versus 46.4, the lowest result of 2024. The forward-looking indicator, also known as the FLI, inched lower at 51.4 versus 52.3 last month, the fourth straight month above 50. Fastener Distributor Index data is collected and analyzed by the FCH sourcing network in Baird. The FDI seeks to identify demand, pricing and outlook trends within the American fastener distribution industry. To get some insight on these results, we’re going to talk to Tim O’Keeffe, Chief Executive Officer at Huyett. Tim, thanks for joining us on the Fastener News Report.

Thanks for having me. I appreciate being here

It’s good to have you back on. The last time you were here was in July of 2024, so things have decreased slightly. What do you think about the latest FDA results?

Quite frankly, it’s a little bit mysterious to me right now in that it doesn’t necessarily jive with what I feel like I’m hearing out there. I’ve done some more skill study and research on this. What I find interesting is I’ve tried to use some of the data that you see that the ITR guys do. They speak a lot in our industry and study the FDI from a three-month moving average the way they measure it. Interestingly enough to me is that if you look at the MMA, it’s actually been bullish, which is a comparison of three-month moving average of this year to the same period of a year ago. Yet when I talk to people out there in the industry, I’m not necessarily seeing that bullishness.

Maybe to be more specific and tie this to the period of time we’re at, I feel like if you were to put a headline on the calendar year 2023, I think I would say softening end user demand inventory correction. If I were to put a headline on 2024, I think I would say soft demand, significant sector difference concern about the election.

We’re recording this in early January, so the election’s now a couple of months past. I think there might be some reason for conditional optimism and we used to see a lot of differences in certain sectors. The ag people are really having a tough time. Anybody that’s around capital equipment, like machine tools, probably are having a challenging time. Yet maybe at the other end of the spectrum, anybody that’s around building in construction, especially red iron, those guys are on fire and doing very well. It’s very choppy, very sector-based right now

Hard to get a clear picture on it.

It is. I try to look at the leading indicator number and always try to reconcile that to the actual FDI number. One thing I find interesting is if you do a 3MA on the leading indicator and the actual indicator, the leading indicator has exceeded the actual indicator every period since the inception of this. Prior to this, I reached out to Eric to try to get the data and he gave me data all the way back to 2012. Since 2012, on a three-month average, the FLI has never not once exceeded the FDI. What that tells you is that the FLI is an optimism emotional number.

Everybody’s optimistic.

We’re overly optimistic all the time. I think I would just leave it at that.

That’s not a bad thing, I guess. It’s good to note that it’s emotional and I think one of the things you talked about last time is the emotionality about the index.

If you look at the numbers, there was a decline for a few periods there. When you look at through the year, we were only below 50 one time, this is on the FDI, and that was in in February. We’ve been above 50 every month since. If this is treated like some of the other purchasing manager indexes and such out there, a reading above 50 would seem to suggest improving number. I don’t know. That’s on a moving average basis. I might’ve said that just a little bit confusing there and I regret that.

The FDI, like you said, finished below 50 at the end of 2024, but the FLI stayed above 50.

Yeah. The last two months in particular, we’ve seen on the FDI pretty low readings 46.4 in November, 48.1 December. I’m thinking with the election settled and there’s not an opposition, there’s no contest of the election, you remove that. That just tells me that underlying, people are seeing softness even if you take the emotions out of it. It does feel like it’s a little softer right now.

Getting into the actual numbers, we had sales, employment, respondent inventories and pricing were all down in December. Supplier deliveries and customer inventories rose. We got an increase in the FD and I think it was driven by the six-month outlook, which is tapping into that forward-looking emotional thing. In December, it made a massive jump. Sixty-one percent of the people expect things to be better in 6 months, 24 the same and only 15 worse. It’s really bullish.

I just attribute that maybe to just the relief of the election over. It’s a very contentious election. I’m not taking a side one way or the other, but both “sides” were really emotional about their candidates. It caused a lot of just churn emotionally. That’s what I attribute this to because really when you look at the fundamentals, there isn’t really a lot to be optimistic about in terms of end market demand for next year. You have a what has been proposed as a tariff on China, Mexico, and Canada. It’s going to be a drag, especially in our industry.

When you look at the fundamentals, there is not really a lot to be optimistic about in terms of fastener market demand for next year. Share on XWe had an economics report earlier this week where employment jumped. I think the feeling there is interest rates are going to stay high, so there’s no relief there. The question is where is this demand going to come from? I did see that the IRS is going to send about $2 billion out to people that apparently were qualified for stimulus relief money and didn’t get it. That might be a little shot in the arm, but otherwise, my thinking is there isn’t a lot there in a stoke underlying demand unless you’re in a sector that’s enjoying something unique. In the Red Iron business with data centers, the increase in electrical demand around AI, those guys are doing well.

We have a sister magazine in the wiring cable industry and those two areas are doing very well. Grid reinforcement as well. Internationally, there’s a lot of focus on Mexico. You mentioned the potential tariffs and all that stuff, but there are a lot of people moving into Mexico in terms of operations and putting in satellite offices, etc. It could be interesting and also hearing good things out of out of India as well.

I think that there are actually a lot of people in our industry moving operations into Mexico following their end user customers. John Deere’s announced a couple of operations they’re going to set up down there. I’m familiar with a number of manufacturers that are moving down there and I think people in our industry distributors are following that business down there.

You mentioned the relief of the election being over, and then that was followed by the threat of tariffs.

One thing that really shocked me was I saw a newsletter. They did a survey and it said that there’s a majority of people in our industry that favor the tariff. I’m trying to figure out who they talk to because it’s going to create extra work as people try to manage this increase in price, or I should say landed cost. I do think the Chinese government will weaken their currency, but that’s going to take some time to play out.

I would think that the Chinese suppliers might cut their invoice price to try to help offset it, but it is still a lot of distraction and a lot of extra work. Some people are trying to resource to other countries. Some of the Chinese manufacturers are obviously moving production to Vietnam and Malaysia. It’s a lot of distraction. I’m surprised anybody in our industry would be in favor of it. I may be reading from a different new newsletter, I guess.

I think also it’s possible that these are just threats to increase negotiation stances, especially on North American ones.

I think they could, and I’m not making a political statement here. I’m just observing conduct from prior paradigms, and when I look at the reaction of Justin Trudeau in Canada, he resigns and flies to Mar-a-Lago prior to making that resignation. I think that probably is the type of approach that suits the Trump administration better. It probably enhances the odds that maybe these types of sanctions won’t happen on Canada. Whereas in Mexico, I think that the president of Mexico threatened to retaliate with terrorists. That approach probably doesn’t work as well. The Chinese have been noticeably silent. My sense is that the China and the Mexico one are probably a lot more probable than the Canadian one at this point.

Good observation there. All right, we’ve got to have some problem to focus on, right?

That’s right. If this were easy, everybody would do it.

I wanted to bring up the PMI rose this month. That’s the Purchasing Managers Index, and that rose to 49.3, which is the first time above 49 since last April. That one is moving up as well.

It is. That could perhaps be a signal that you maybe we’re seeing some uptick.

That’s a really broad one.

It is. I look at that on a longer-term basis. It’s only been down when we’ve had recessions over the last 25 years or so, and we have not had a recent recession, although I will say that the period of time in which it’s been below 50 has been longer than any recent stretch of periods in quite some time. It just reflects to me what I call a hangover post pandemic when there was a lot of free business out there. A lot easier to see new business. I think we just chopped along the bottom but that it’s a slightly positive and let’s keep our fingers crossed.

4That seemed like a good sign to me. Let’s move on to the comments and actually, I had a note here about Baird was cautioning readers not to read too much into the end-of-year results due to holidays and weather problems.

We have that every year, although with Christmas on a Wednesday, that might make that week stretch a little longer than normal. I can appreciate that comment.

We have commentary from the people who did the survey and overall probably leaning positive, but then some caution on the tariff issue, which we’ve already started. The first comment was, “It appears things are status quo now that the election and year are over. We don’t expect much in the way of overall business jumping, but field domestic manufacturing will benefit from the latest tariff talks.” There’s another one of those pro-tariff people.

The next comment says, “We continue to be nervous about Trump’s new tariffs. They will affect everything. The higher they are, the worse the overall impact.” I would fall into that camp, I think. That being said, as a sidebar, I don’t like when people dump products. It’s always a problem and there’s never a good solution to it. The next comment is a little bit more on the business side. “RFQ slowed in much of December, so we were unable to capitalize on as many orders as we had hoped to. Hopefully the large number of business days in January will help us balance it out.”

I guess the thing I would just take away from that is that I’m surprised that over the last year or so, there have not been a lot more market testing among end users in production fastener distributors. There were a lot of price increases to be had as we went through the post-pandemic recovery where the pricing equation leaned heavily on the supply side versus the demand side.

I expected, as demand has softened and end-user OEMs have had maybe more time on their hands to market test, that we’d see more market testing. Quite frankly, we usually see market testing. We will see the same inquiries from 3 or 4 distributors that are being tested. We haven’t really seen that yet. That surprises me and this comment also reinforces it. We’re just not seeing as many RFQs out there. I’m surprised by that given where we’re at in the business cycle and the relatively recent inflation that’s happened in our industry. That comment caught my attention, most certainly.

Definitely something to pay attention to. All right. We got three more comments. It says, “Early December sales were better than expected, but slowed to expected levels as we hit the holidays. Expecting quoting activity to be the same, but incoming POs could be higher.” The last two are both positive. It says, “2024 was a very strong year for us, and we have higher expectations for the new year.” The final one is, “2024 will be our second high second best behind 2022. Hoping 2025 brings good things for all.”

Those seem like micro-type comments that are probably unique to a particular individual or company. It does seem interesting that in the first comment, they’re talking about incoming POs could be higher, which suggests just an underlying demand improvement from the end user market. I think if you look at right below here, you’ve got Fastenal in the report. When you look at Fastenal sales, I don’t think that Fastenal would necessarily share that ‘24 is their second-best year behind ‘22. I think that some of the other bigs probably would find that to be similar. Some of these comments when you get at this level get to be pretty microscopic and are pretty unique to specific companies and survey participants.

Maybe the people had good years. They just want to talk about, which is not a bad thing. Anything else you want to add to the FDI or FLI discussion?

I do hope that we do see a pickup in demand and I think some things that’ll be early to look at as we start the new year are reflected in these comments here. Do we see an increase in RFQs? Do we see increases in purchase orders? Are there any other macroeconomic things that would be good signals? I’m waiting on the year with bated breath and hoping we start to see these things pick up.

Making Huyett A Sustainable Evergreen Company

Hoping for the best. Alright, so we get to the point of the talk here. We’re going to give you a chance to tell the readers what’s going on at Huyett and, in particular, I saw you had a blog post on your website at Huyett.com/blog where you’re talking about creating a sustainable evergreen company. I thought maybe you can be an entry to talk about that a little bit.

It is something that we’ve been working on. We are a privately owned company. My wife and I own Huyett. I would like to live forever, but that probably is not going to happen. We’ve commenced a process over the last couple years to talk as a family system, very transparently with our team members as well, on the notion of trying to remain a private company for another generation.

I was admitted into an organization called the Tugboat Institute. It’s a very interesting and inspiring organization founded by a former private equity individual from Silicon Valley. He had a client at one point, they were going to exit and monetize their investment, and she resisted, and it caused him to think deeply and look into the whole idea of private companies and remaining private. As a result of that self-study process, he started this organization. There are about 300 companies give or take in it right now. We span all industries almost every state in the union.

It’s been a really good experience for me to network with other CEOs who have similar aspirations. We’ve been working on this as a company ourselves, and I’m not sure if we’re going to be successful. I certainly hope we can be. Our industry, like many, obviously has a lot of influence with private equity, and that’s something that we probably will continue to see happen.

The private equity people are good if you’re an investor and have done well. By the same token, typically, if a company is bought by private equity, they’re for sale the day it’s purchased and we’ve seen this with Big Bolt, and they have been purchased by the LindFast Group. Big Bolt, the Partridge Family sold that business out a few years back. We see this whole investment orientation, and at least for me, I don’t want our employees to become simple social security numbers. I’m cautiously optimistic that, through a process, we can certainly try to remain private.

Steer the direction of the company.

It gives us a long-term perspective. It gives us a really employee people-driven first psychology and so I feel like for us, it can actually be a competitive advantage.

I think it’s good. I encourage readers to go read the whole post there. You’ve touched on some of the points there with the private equity you’re being for sale the next day. I think it’s good and it’s good that you’re looking at the whole thing and then you close it out. You say you focus on culture growth and internal succession planning. That’s good to hear. It’s refreshing to hear.

The founder of Tugboat Institute, his name is Dave Whorton, actually published a book called Another Way: Building Companies That Last…and Last…and Last. He wrote it with Bo Burlingham. Some of you might know of him. He co-wrote The Great Game of Business with Jack Stack, which is a really popular business book out there. If people are interested in this further, that would be a recommendation of some additional study if anyone’s interested.

Moving Forward With An Optimistic Mindset

Readers can check it out at Huyett.com/blog. It’s posted December 18th, 2024. The other thing I wanted to bring up is I saw you had a LinkedIn post right at the end of 2024. It got my attention. It made me laugh and think at the same time. You posted what you considered a Christmas card to your professional network, which was a video, which I’ll talk about in a minute, but at the end of the post, it’s very short and to the point. It says, “2025 will be the best ever. If you don’t believe that, retire or quit.”

If you can’t go through life thinking that tomorrow’s going to be a better day, it makes a living today hard, doesn’t it?

Yeah. I think that’s what I thought you meant. You weren’t saying you had some special knowledge about 2025, but this is the year in front of us, or these are the days in front of us, so make them the best ever or get out of the way.

You bet. I live every day thinking that I can make the world a better place tomorrow. I hope everyone in our company does that. I think there are a lot of people in our industry that feel the same way. I think that 2025 will be better than ‘24, and I’m very invigorated and excited about that. I think a lot of other people are as well.

I appreciated that and like I said, it made me laugh and think at the same time. You updated on your son Tommy O’Keeffe, who’s a singer-songwriter, and you posted his video there. I think a lot of readers have already checked it out, but if you want to give us a little bit of background on that.

I’m really glad that you brought it up. I feel like this is like a self-promotion deal, and I don’t mean that to be this way. My son Tommy is a very interesting story. He moved to Nashville to be a singer-songwriter. He’s published probably, I want to say, 14 or 15 songs. He wrote many of them, almost all co-writes. One thing I’ve learned about the singer-songwriter endeavor is most songs are co-written. I think that the writers get a little bit more strength and also, the notion that you can view a song, whatever the message is, through multiple lenses. The song that Tommy put out recently was one he wrote by himself.

He recorded a little family video with it. It’s been a very enjoyable. It got a lot of airplay, and so we’re excited. I just have to tell you that probably the hardest thing in the world to do right now is build a music career because streaming has changed the economics profoundly. He’s got a long journey ahead, but it’s really a great song and it’s done really well. The song’s called When I Do, so if you get a chance, you might check it out.

If you cannot go through life thinking that tomorrow will be a better day, it makes living today hard. Share on XPeople can check it out. It’s on his YouTube channel, which is Tommy O’Keeffe. It’s got a lot of family videos in there. You guys were doing some celebrations and maybe give us the backstory on that.

It’s really his gig, I guess, is what I’d say.

Right, but you guys are all in it.

He’s at an age where there are a lot of weddings in our life right now. We went to a lot of weddings in 2024 and so this song’s about making a long-term commitment. The video is a series of some of the weddings we attended. My son got married in September 2024 in a redwood forest near Santa Cruz, California. There are some video shots of that. It’s all about the long-term commitment. Speaking myself as someone who celebrated my 40th wedding anniversary in 2025, if you’re lucky enough to find the right one, it sure makes life a lot shorter and a lot better. The song reinforces that. There’s a lot of family videos on there with a lot of weddings.

I’m not sure how many kids you have, but I have to think that maybe you probably have some kids with grandkids perhaps, and it certainly changes your life and it puts a smile on your face. I guess it’s another reason why you can say that tomorrow’s going to be a better day because it’s another day with my grandkids.

There you go. How many grandkids do you have?

I have five right now. I have five kids. I have five grandkids only with my oldest son, Jim. They’re all five and under. That’s called chaos.

I’ve got a couple of kids. No grandkids yet, but tomorrow’s another day, so there you go. I appreciate the video too because in this day and age, you lots of press about AI and all these shortcuts and even mentioned on the streaming of music, I know there’s a lot of fake musicians out there too. It was good to see a real musician and a real family, and the whole video. I enjoyed that.

It’s interesting that you mention that, and I hope I’m not getting us off too much in a tangent here, but I’m actually taking an AI certification course right now. I want to learn about this and it’s teaching me how to make prompts on ChatGPT. What I can just offer is that it is astounding what you can produce with AI. It’s so far beyond an individual’s own ability to comprehend.

I feel like the first week learning cursive writing when I was a kid in school. This AI thing is crazy. Increasingly, it’s going to make, in some ways, the world a more dangerous or unsecure place in that everything from cybersecurity and such like what’s going to happen to the art world both the visual arts and the audio arts when you have computers that can record all this stuff. My son’s the real deal. He is not an avatar. What you see is what you get.

AI is crazy. It increasingly makes the world a lot more dangerous or unsecured place. Share on XYou guys can check it out and if you want to see Tim’s post, it’s on LinkedIn and Tommy’s things on YouTube. They’re both there. Tommy’s things on YouTube. Job well done. Congratulations to your family, and everything. Anything else you want to add about Huyett before we wrap it up?

No. I just would wish everybody a good year, a happy 2025. Mike, I always appreciate what you do in the industry and Eric as well. I hope all is well. I appreciate the opportunity.

It is. And we’re looking forward to the 2025, and I like the numbers that they both divide into 100. I don’t know what that means, but I like the look of it. Thanks for joining us on the on the Fastener News Report.

Thank you.

Tim Roberto Jr. On The Latest Huge LSG Acquisition

That was Tim O’Keeffe. He’s the Chief Executive Officer at Huyett. The FDI number for December 2024 was 48.1 versus 46.4 in November. Visit FDISurvey.com to participate in the process and get a detailed PDF copy of Baird’s monthly analysis. Now for today’s top story, LindFast Solutions Group, also known as LSG, completed the purchase of Big Bolt LLC, a leading domestic manufacturer of specialty fasteners and an end-to-end solution provider with industry-leading turnaround times.

LSG Management says that the company is excited to welcome the Big Bolt team, and is confident that together, the group will continue to offer customers unparalleled service quality and product availability. Big Bolt supplies, high-quality special fasteners, serving distributor customers across diverse markets. With a focus on quick turnaround times, comprehensive in-house fabrication capabilities, and unmatched product quality, Big Bolt is the go-to supplier for highly customized low-volume orders and more.

LSG looks forward to expanding Big Bolt’s ability to serve its collective customers by leveraging LSG’s significant base of fastener expertise, sales force experience, inventory, and physical locations across North America. The company is confident this combination is very powerful and will continue to establish LSG as the provider of choice for all fastener needs focused on creating value for customers, suppliers, employees, and stakeholders.

LSG is a master distributor of standard and specialty fasteners in both metric and imperial sizes. The company also provides customers with a range of value-added services, such as packaging, plating, coating and guaranteed stock programs. Eric Dudas caught up with Star Stainless screw president Tim Roberto Jr. to get his input on this story.

—

Another big announcement from LindFast Solutions. Tim Roberto Jr. with LindFast. Star, of course. He’s here with us right now. Tim, what’s going on? What’s the big headline with Big Bolt? We’re dying to know.

Thanks for having me on. I appreciate giving us the time. Exciting news for us. This was an early Christmas gift for LSG, the Big Bolt acquisition that took place in late December 2024. We’re excited about what this opportunity and this company offers the LSG family overall.

Let’s get into just a couple of the obvious details. For folks not really that familiar with Big Bolt, they’re quite an interesting company. I’ve always felt they do all sorts of small to mid-size fabrication projects and recently, of course, folded in Delta Secondary into their group, now part of LSG as well. What else can you tell us about Big Bolt?

I think what Dan and his team is set up there at Big Bolt is just customer-oriented, driven completely by customer need. Quality has been big. Just the quick turnarounds that they’re able to offer, it’s just amazing to be able to see. Partnered with Mega, which is part of Lindstrom right now, these two are really a beast when it comes to serving customer needs.

Just amazing how they’re able to turn things around so quickly from the inventory that they hold, but also just that drive and desire to meet customer needs. It’s just amazing to be a part of and to see, especially when it comes to manufacturing. I think too often, the manufacturing side of things is often that you’re going to get what you’re going to get and you’re going to like it when you get it.

For us, to see companies like Big Bolt and Mega working together where we want to make sure you’re happy, we’re going to turn it around in the time that you want it. I’m going to make that happen in just amazing ways. I think for us, it continues. I give credit to Alex Acosta, who’s our head of corporate development, and Bill Nikita, the CEO, who have just kept their ears to the ground for companies that would complement who we are.

I think Big Bolt is a huge compliment to what we try to offer at LSG, which is always customer-driven, customer-oriented. We’re ecstatic to be able to add them to the portfolio. Just ecstatic for what Dan and his team offers customers. I think partnering together with the other divisions that we have, I think this really continues to complete a portfolio and offering that we’ve wanted to have.

You answered a couple of my questions in that comment right there, Tim. I think this probably answers the one that I was going to ask about LSG’s thinking on the trend of domestic manufacturing. Can you expand on that a little bit more? Obviously, that plays into that idea.

I think for us, it’s definitely targeted and warranted for manufacturers who can present to customer needs, who have that opportunity to continue to compliment what we’re already offering. I think this was just a no-brainer when it comes to Big Bolt. They’ve proven that over and over again. To your point, they’re an amazing company that doesn’t get a lot of notoriety. I think the customers who do know them continue to come back just because of the experience they’ve had. Getting their name out there and leveraging the relationships that the overall LSG team has will be just a win for the overall industry.

When you’re partnering with domestic manufacturers, you want to make sure you have those right partners. I completely agree that Big Bolt would be an amazing partner for anybody who’s looking for big runs, small runs, quick runs, long runs, whatever it is that they’re needing. I think Big Bolt wants to answer that and they’re hungry to do it, which is just amazing to see. Dan and his team really have formed a just a team that wants to meet every single customer need that they can. It’s just amazing to see it then come to fruition and done. For me, I’m excited to be part of LSG that just continues to grow in many ways, adding key partners that make us better.

You always have your eye on stainless. You go way back with Star Stainless. You’re the president of Star Stainless, Tim Roberto Jr. Before I let you run, what are you seeing out there specifically regarding stainless?

What we’re seeing is just a continual slowing of worldwide demand. I think that’s really just holding the worldwide price down as well. That’s why you’re seeing nickel not take off like it wants to. The US has been carrying that market for so long. I think the hope and the bated breath is what’s going to happen with China. Are they going to get back in line with their consumption of nickel or is it just going to continue to be soft? That’s what we do. We monitor that to see how the worldwide demand goes. As that goes, that’s where you see the price goes. For us, we try to stay ahead of it, get ahead of on the inventory to make sure we have the right inventory at the right time.

For us, it’s been continuing to expand that inventory. That’s been an exciting thing that we’ve seen over the last three years, just an expansion of the offering that we have to be able to be that one-stop shop to carry the things that our customers need. I think we’re going to continue to see stainless grow I would say over this next year of course. In the future, I think it’s a natural tendency for stainless to continue to grow, but for us, it’s making sure that we have the right product at the right price and that our customers get what they need when they need it.

Alright, Tim, well thanks for the summary. I won’t talk tariffs right now because we’re all still in wait and see mode, but next time for sure.

As it unfolds, the hard part now is you just see little news bits that keep dropping and there’s still so much uncertainty. You’re right. I’d love to talk about that at a later date.

Thanks for being here. We’ll talk to you soon.

—

More Fastener Newsmaker Headlines Today

That was Star Stainless group President Tim Roberto Jr. and Eric Dudas. Next up, today’s Fastener Newsmaker headlines. In corporate news, Bolton plans to establish operations in Vietnam. Big Bolt acquired a powerful tester thread roller. Century Fasteners received accreditation to AS912B. NEFCO acquired Unistrut Midwest. Anchor Bolton Supply partnered with Birmingham Fastener. Prime Source brands acquired Harney Hardware. Spiral expanded its precedent inserts line to include aluminum products. Vico products announced a new website. R&S Industrial Supplies acquired Sasco Fasteners.

Endries International announced a new distribution center in Texas. AFC Industries acquired Irwin Industrial and EJOT won the Volkswagen Formel Q certificate. In personnel news, Suncor Stainless appointed Don Piccirilli as new West Coast Senior Regional Account Manager. Blackhawk Industrial promoted Jay Costa and Anthony DeSalvo. Dormant Products appointed Tayfun Uner as President of its Light Duty Business Segment. Bolton Nut introduced Adam Williams as its new Quality Director.

Auveco appointed Ed Gerber as CEO and Brighton Best International, also known as BBI, announced that Alfonso Paniagua, Regional Manager from Brighton Best Dallas and George Hunt III, Regional Manager of BBI Chicago, have successfully completed and passed the final exam to earn the Certified Fastener Specialist designation, also known as CFS from the Fastener Training Institute. You can get details on all of these stories and more in Fastener Technology International Magazine and the Fastener News Report monthly newsletter, both available online FastenerTech.com.

Now let’s turn to the back page to talk about signposts on the Wisdom Trail. The end and beginning of any year. Always have a good share of big idea essays, opinions and commentaries and all levels and types of media. Earlier on the Fastener News Report, you read Tim O’Keeffe’s advice for this new year of 2025, as he succinctly said, “2025 will be the best ever if you don’t believe that, retire or quit.”

To that, I would like to add another favorite of mine, which comes from Wall Street Journal Pulitzer Prize winning columnist Peggy Noonan. The title of her January 2nd, 2025 entry bears the title of this month’s Backpage Report, Sign Posts on the Wisdom Trail. The subhead reads, “Things I learned from Abraham Lincoln, CS Lewis, David Foster Wallace, and my friend’s grandmother and others.”

Here are seven selected signs of wisdom told from the author’s first-person voice. Number one, an Italian grandmother was stirring sauce over the stove as I, about age ten and my friend, her granddaughter, fantasized about how a local family must be rich millionaires. They just bought a big car. “Don’t count other people’s money,” the grandmother said. “You don’t know all the facts and it’s none of your business.”

Number two, I once read that Abraham Lincoln said, “If you ask most people to put all of their troubles in an open sack and place it down next to their neighbor’s sacks, and then everyone was told to pick one up and keep it, most people would hesitate barely a moment before they picked up their own sack and took it home.”

Number three, the only truth to tell a young couple about to get married, God is real and babies are everything. The only advice for a college graduate, honest work makes the world go round. Bring your talents to market. The most important thing to tell a student entering college or high school, read. Number four. To paraphrase CS Lewis, “Empires rise and fall, great nations come and go but the man who poured your coffee this morning is immortal because his soul is immortal.”

Number five, from a journalist friend this week. “You are never sorry you took a walk.” Another writer told me a few weeks ago of his New England Yankee mother who’ll believe there are no problems that aren’t made at least slightly better by a long walk and none that are made worse. Number six, a man in his early 80s told my friend, who was a psychologist, that he really wanted to do was learn Italian, but that it’s absurd to be likely dead in ten years. What would he do with it?

The therapist said, “You can die knowing Italian or you can die not knowing Italian. Which is better?” The old man studied Italian happily. It’s never too late to begin. Number seven. On a piece of paper above my computer is a quote from David Foster Wallace. “Good writing isn’t a science, it’s an art and the horizon is infinite. You can always be better.” In closing, she says, “Go forward this year, whatever your field, like an artist.” To that I say, amen. This has been Mike McNulty of Fastener Technology International Magazine, bringing you the Fastener News Report. Please send your news, pictures, comments, corrections, or complaints to me at McNulty@FastenerTech.com.

—

Risk Mitigation In Structural Bolt Tensioning With Carmen Vertullo

This is Carmen Vertullo with the Fastener Training Minute coming to you from the Fastener Training Institute in Carver Labs in beautiful El Cajon, California. Our topic rises out of an incident that we processed on a job site, structural steel job site. My lab manager and I, lab manager Rick Wiley, thank God for Rick, went to the job site with our Skidmore-Wilhelm Bolt Tension Calibrator to solve a problem that was created by the erectors because they took some unnecessary risks.

Fortunately, we were able to solve that problem, but we can’t always solve these problems. I’m going to tell you about a particular risk associated with structural bolting and it informs us about all kinds of other risks that occur in the fastener business. Fasteners is a risky business. There’s lots of things in life that are risky. For example, driving a car is risky. However, there are all kinds of things that we do to mitigate that risk.

We have great roads and laws and insurance and we have to get a license and get trained and we manage risks by like not driving when we’re impaired and we don’t speed and so on. Driving is a manageable risk. However, if you were to drive in Baghdad, which I have not driven in Baghdad personally behind the wheel, but I’ve been in cars there, the risk is unfreakingbelievable because they don’t have all that cool stuff that we have here to manage our risk. Tijuana, the same way. Not quite as bad as Baghdad and I have driven through Tijuana.

In our fastener world, we have all kinds of cool barriers and guides and rules and just good common practice that helps us manage the risk. Otherwise, this business would just not be doable. When we don’t follow the rules, we end up suffering the consequences of that risk. I’m going to tell you a story about that right now.

There are all kinds of barriers in the fastener world. Rules and good common practice help everyone manage the risks. Share on XI got a call from a steel erector here in San Diego putting up a building, nice steel building, beautiful building. It’s an office building. What they’re using in this office building some very large, very strong structural bolts. As a matter of fact, they are the largest and strongest structural bolts that we have. They’re ASTM F3125, grade A490 hex cap bolt, heavy hex cap structural bolts and nuts and washers, plain steel. The size is inch and a half, largest they come.

In the structural world, one of the ways that we mitigate the risks associated with structural bolting is we have a test called the PIV test, Pre-Installation Verification tests. I’ve spoken about this before on the Fastener Training Minute. The PIV test requires that before we put any bolting in the steel, we prove that it is going to perform as required. That is, it’s going to develop the tension required in the steel using whatever our method of tightening is.

The standard that we use is called the RCSC specification for structural joints using high strength bolts. It provides for five different methods of tensioning. The most common method is called turn of the nut. That simply means we snug tighten the bolt and then we turn it a certain number of degrees and we get the proper tension.

Another method is using a calibrated torque wrench. That’s a very rare method, not that good of a method and as a matter of fact, it’s going to be removed. A third method is the combination of those two where we use the torque wrench for snug tight and then we use the turn of the nut for the final tensioning. That’s going to go away as well.

Another method, which is one of the most popular, is the tension control bolt, the twist off tension control bolt. I’m not going to explain what that is right now, but it’s a really cool fastener. The final fifth method is a device called a direct tension indicator. This looks like a washer and it is a washer that has bumps on it. Those bumps are very specifically calibrated to be able to indicate the tension achieved.

The way it works is the bumps are pushed from one side of the washer during the manufacturing so it actually makes an indentation on one side and a bump on the other side. Just imagine you’re going to maybe poke your finger into something soft like a piece of dough and it makes an indent on one side and a bump on the other.

We put this in the steel and we tighten it down and the bumps collapse and we measure the gaps between the bumps with a feeler gauge. It’s a little bit more complicated than that, but that’s how it works. For this all to be effective, whatever method we use, we have to prove with the special inspector that it works. The way we do that is we have a device called the Skidmore-Wilhelm Bolt Tension Calibrator, commonly just called the Skidmore. This device is a hydraulic load cell with a gauge attached to it and the gauge reads and pounds force not PSI.

We can actually put the bolt in the nut combination in the Skidmore, use whatever tightening strategy we have, prove that it works three times, inspector’s happy, we can now put the bolting in the steel. I’m going to read something to you from the RCSC standard section seven on PIV testing. This should be tattooed on every keg of structural bolts that goes out. Actually, some suppliers do this. Some suppliers that I’ve counseled do it.

It says this. “Pre-installation verification testing provides a practical means for ensuring that non-conforming bolting assemblies are not incorporated into the work. Experience on many projects has shown that bolts, nuts and/or bolting assemblies not meeting the requirements of the applicable ASTM standards would have been identified prior to installation if they had been tested as an assembly lot in a bolt tension measuring device. The expense of replacing bolts installed in the structure when the non-conforming bolts were discovered at a later date would have been avoided.”

Very classically important piece of information there. It turned out that because they did not have the proper Skidmore-Wilhelm Bolt Tension Calibrator, they did not do the PIV test on these direct tension indicators, which was their method in this instance on these inch and a half a490s. This building is almost 100% built. You can imagine the size of these columns that are using these inch and a half a490s.

The problem is there are two basic models of the Skidmore-Wilhelm Bolt Tension Calibrator, the MZ and the HS. The MZ is the smaller model and it can achieve tensions of 126 kips. The HS is the larger model and it can go to 170 kips. This was such a large and strong bolt. As we said, the largest, strongest structural bolt we have an inch and a half, A490 and the erectors did not have the HS model, they only had the MZ model, they could not do the PIV test on the direct tension indicating washers, so they just skipped it.

Lo and behold, when the inspector went to check for the results of that test and they weren’t available, they said, “We’ve got to do this test.” Parts were already in the steel. We happened to have an HS model here at Carver Labs. John O’Brien informed the client of that. They called us up. Carver to the rescue. We showed up on the job site with our HS tension calibrator and we did their test and they passed. Thank God. I cannot imagine what the result would’ve been if those dtis did not pass the test. It would’ve been a disaster.

I have a very similar issue right now. Fortunately, it’s only about 800 bolts and they’re three-quarter-inch twist-off tension control bolts. Those bolts are being removed because they failed to do the PIV test prior to installation. When they went to do the PIV test later, it did not pass. However, those bolts were left out in the rain and so they had a compromised lubricant on them. Could not pass the test. They couldn’t prove anything about whether they were good at the time of installation.

Fortunately, my client, the supplier, provided product that was in compliance and the erector will pay the expense of replacing those 800 bolts. There are also other options. You could do a thing called an arbitration test on the installed bolting and that could be a way to keep it in place. All of these things are things that anyone involved in structural bolting, suppliers, manufacturers, installers, sellers, buyers, consultants, test laboratories all should be very well aware of, especially the workings of the Skidmore-Wilhelm Bolt Tension Calibrator. We have training here at Carver Labs and be looking for this by the way, because we have some clinics coming up. We’re going to do multiple clinics here and you’ll be hearing from us or FTI about those.

One more final word I would like to say is if you don’t own a Skidmore-Wilhelm Bolt Tension Calibrator and you’re in the structural bulk business, you should own one. Please call me and I will help advise you on what you should get. I know that Skidmore-Wilhelm has a backlog right now of manufacturing these. You might not be able to get one by snapping your fingers, but you need to get on the list. By the way, Skidmore-Wilhelm also produces other types of bolt tension calibrators for smaller screws where we can test automotive screws, screws used in medical devices and other types of equipment.

They also produce torque testing equipment. They have a full menu of excellent bolt testing devices to help us know that our torque tension relationship or whatever our tightening strategy is will work in whatever application we have. At the end of the day, I just want to tell you all, be aware of the risks involved in your fastener transactions. Mitigate them and let’s make sure what you sell stays sold, stays shipped, and you get paid. We don’t have to have any rejections, any returns, and god forbid, we don’t have to remove and replace bolting that has already been installed in structural steel. This has been Carmen Vertullo with your Fastener Training Minute. Thanks for reading.

—

Episode Wrap-Up And Closing Words

I am back to wrap up another one. We don’t always have Brian with us.

Sometimes we do.

When we do, it’s much better. Brian, glad you made it back.

It’s all right. I know, me too.

This is a ginormous scrubber project this time, huh?

Yes. It’s very large and the biggest one we’ve done, actually. Very complex and it’ll take us a little while.

Alright, that’s what we do. Thanks for jumping on, Bri. We have a great show that’s all in the can. You caught the tail end of it, but that’s all right. We’ll have plenty more as 2025 unfolds. Hopefully, many more scrubber jobs too.

Not quite like this for a while.

Fair enough. Let’s wrap this one up and we will think about that then. The title sponsors of Fully Threaded Radio are Star Stainless. Right off the shelf, it’s Star. Goebel Fasteners. Quality the first time. Go Goebel. Brighton Best. Tested. Tried. True. Brighton Best. Fully Threaded Radio is also sponsored by Buckeye Fasteners, BTM Manufacturing, Eurolink, Fastener Supply Service, Fastener Technology International, INxSQL Software, Fastener Fair USA. J. Lanfranco, Solution Industries, Volt Industrial Plastics and Wurth Industry North America. You know the email address, folks.

Use it.

That’s right. It’s FTR@FullyThreaded.com. Let us know what you think. Got a question or suggestion, here we are. Actually, Bri, you’re not going to have a very big role in the next episode either. No fault of your own. This time, you’re off the hook because it’s really just a ginormous discussion with Skidmore-Wilhelm top guy John O’Brien, along with everybody’s favorite torque tension person, Carmen Vertullo.

In the Fastener Training Minute, Carmen suggested that he was going to strongly advocate to get this thing going. We wasted no time. As soon as he got done recording this one, I said, “Give me John’s number. We’ll set it up.” We did, and the conversation is epic. In keeping with our new tighter format, I didn’t want to tack it on this thing, otherwise, it would’ve been pretty long.

Put it this way, it would’ve made Tom Budden bone very unhappy, Bri. If you’re into torque tensioning and the Skidmore-Wilhelm and all that, it’ll be something you won’t want to miss. We’ll drop that one right away. As 2025 unfolds, Bri, there will be plenty of chances for you to share your wisdom, humor, and general knowledge on the audience. Don’t worry. We’ll put episode 208 in the can, everybody. We sure do appreciate you clicking in.

We do, even on the tail end.

Pay attention to your texts, Brian, a little closer. I know you get really into the concentration zone, but I tried. Get out there, sell some screws.

See you next time, folks.

Talk to you then.